Auto-focus Microscope Application Of Rubber Parts Appearance Inspection

Rubber products are widely used in industrial production, with the refinement of industrial technology, the quality requirements of rubber products continue to improve, need to do a good job of strict testing.

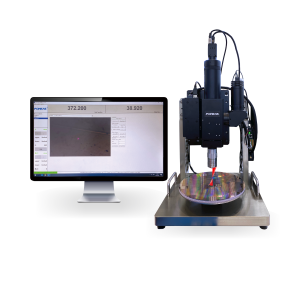

With the rapid development of modern industry, rubber parts inspection equipment has been greatly improved. Some modern testing equipment and technology in the rubber products industry has been recognised and applied, such as video microscope, can quickly complete the rubber parts appearance inspection, not only improve the quality of the product and production efficiency, but also pull the rubber products of technological innovation and progress. This article introduces the application of Pomeas autofocus microscope in rubber parts appearance inspection.

Detection needs:

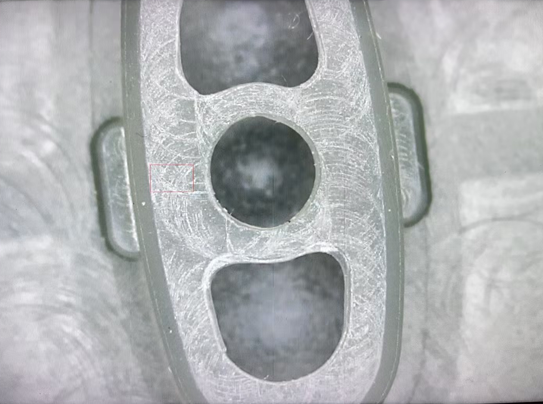

Identify whether there are scratches, pits, black spots, breakage, blockage and other defects in the appearance of rubber products.

Inspection Solution:

The use of Pomeas autofocus video microscope can quickly and clearly complete the rubber parts appearance inspection.

Inspection Result:

Advantages of auto-focus video microscope:

1. can observe the product image directly on the monitor, no need to use the eyepiece, inspection is more intuitive.

2. with real-time focus function, no need to manually focus, automatic identification of the parts to be inspected, effectively saving the inspection time.

3. can be continuously zoomed, quickly change the magnification, adjust the image size.

4. It can store pictures and videos for convenient data saving and real-time viewing.

With high magnification and low distortion, Pomeas auto-focus video microscope has a good performance in mobile phone parts inspection, metal parts inspection, PCB inspection and other fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com