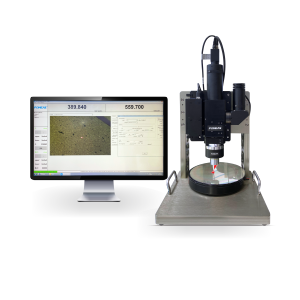

High-contrast Inspection Of Metal Parts With The Application of Pomeas Auto-Focus Video Microscope.

Metal, has always been inundated in people's lives. With the development of science and technology, people's needs gradually developed from a single metal products to multi-metal synthetic products. Detection requirements of metal products are also more and more precise, need to use a variety of high-tech inspection tools, microscope is one of the options.

Industrial manufacturing, metal workpieces, shape, material varies, this article introduces one of the high reverse surface of the metal parts of the detection programme.

Detection needs:

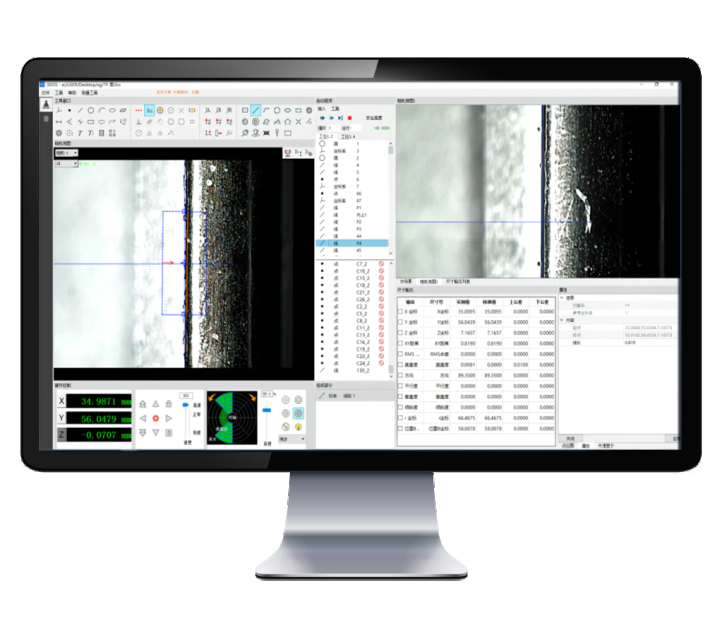

Fast high reverse conical metal parts to identify whether there are defects on the surface, to ensure product quality.

Detection difficulties:

Traditional microscope will form a light shadow on the surface, resulting in the inability to clearly see the surface features.

Solution:

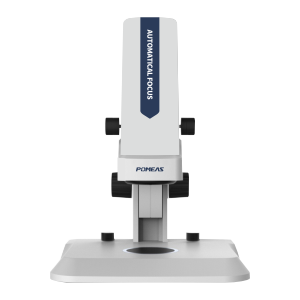

Use Pomeas self-developed large field of view autofocus video microscope, high definition imaging without light shadow, quickly and clearly identify the surface defects of high reverse metal parts.

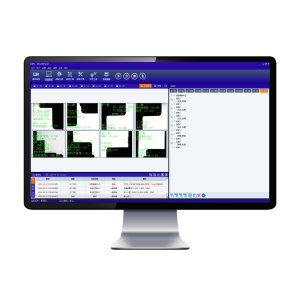

Inspection results:

Advantages of large field of view auto focus microscope:

1. It can realise automatic focusing, with a focusing range of more than 100mm or more;

2. Large working distance, suitable for irregular or oversized product inspection;

3. The operation is simple and easy to understand, the use of the mouse can be free to complete the magnification switch, a key to focus, and has the function of image saving, video and other functions, convenient for inspection at any time.

Pomeas large field of view focusing microscope can be configured and adjusted according to customer needs, suitable for circuit boards, metal parts, mobile phones and other 3C products appearance inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com