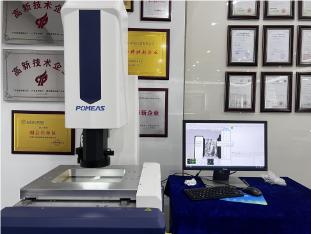

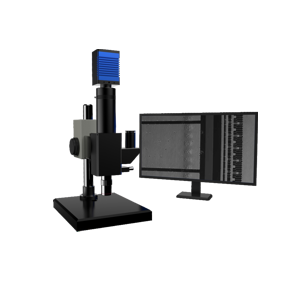

POMEAS HM-1065 On-Line Image Measuring Instrument

The new POMEAS HM-1065 in-line image measuring instrument is redefining the standard of industrial measurement with its outstanding performance and innovative concepts....

How is the pitch of a gear measured?

Gear tooth pitch is an important index in gear geometric parameters, which directly affects the transmission accuracy and noise level of gears....

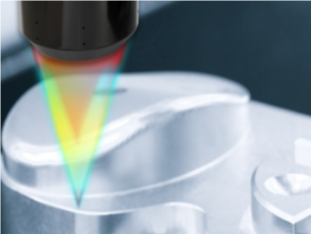

3D Contour Measurement Case: Mobile Phone Camera Module

POMEAS 3D Profile Dimension Measuring Instrument shows great compatibility. It is capable of accurately measuring the flat dimensions of a cell phone camera module, whether it is the length and wid......

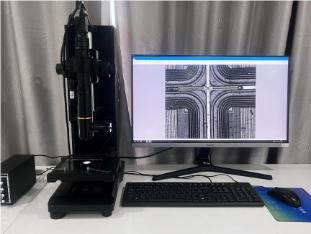

14X zoom lens solution for wafer inspection applications

Utilizing the different magnifications of the 14X zoom lens, various structural dimensions of chips on wafers can be precisely measured....

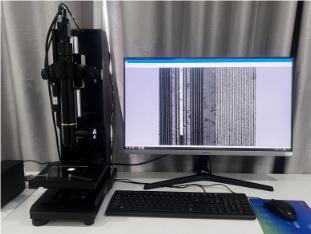

14X zoom lens inspection solution: Wafer Inspection

14X zoom lens inspection solution with 14X zoom lens as the core, HD industrial camera, built-in coaxial and external ring light, and POMEAS MetX multi-sensor measurement system....

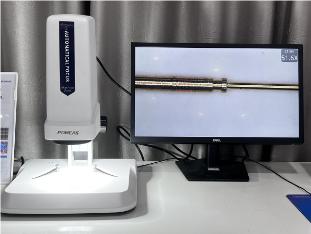

Appearance Inspection of Metal Parts: Probe Measurement

In the production and quality control of metal probes, accurate observation of microscopic features such as imperfections, scratches, and losses on the probe surface is a critical part of ensuring ......

What measurements are often used for surface inspection?

Surface inspection is critical in manufacturing, especially for complex parts such as automobile bodies and aircraft engine blades. There are a variety of measurement methods that need to be select......

Can image dimensioning systems enable non-destructive testing?

Non-destructive testing is a kind of non-destructive testing without destroying the structure of the object under test, without affecting its use of performance under the premise of physical method......

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION