Advantages of fully automatic image measuring machine for measuring dimensions of metal parts

With the development of the manufacturing industry, metal parts size measurement in the manufacturing industry is of great significance, not only related to product quality and production efficiency, but also closely related to industry compliance and technological innovation.

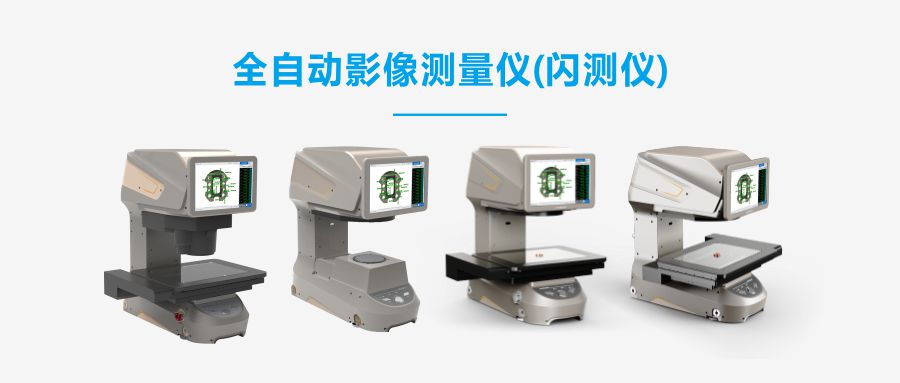

For metal parts dimensional accuracy and efficiency are also increasingly demanding. Fully automated imaging instrument (flash measuring instrument) as an advanced measurement technology for metal parts size measurement brings many advantages. For example:

I. High-precision Measurement

Fully automated image measuring instrument (flash measuring instrument) utilizes a high-resolution camera and sophisticated measuring software, which can realize high-precision measurement of the dimensions of metal parts. Through image processing and data analysis, micron-level or even higher precision measurements can be achieved, far exceeding the measurement accuracy of traditional measuring tools.

II. Fast Measurement

Compared with traditional measurement methods, fully automated image meter (flash meter) can realize the rapid measurement of the size of the metal parts. Simply place the metal part to be measured on the measuring table of the imaging instrument, the system will be able to automatically complete the measurement, and can realize the simultaneous measurement of multiple dimensional parameters, greatly improving the measurement efficiency.

III. Non-contact Measurement

Fully automatic image meter (flash meter) using non-contact measurement technology, do not need to directly contact the surface of the metal parts, to avoid possible damage or deformation in the measurement process. This is particularly important for some of the strict requirements of the surface of the metal parts of the application scenarios, but also to ensure the accuracy of the measurement results.

IV. Data Recording and Analysis

Fully automated imaging instrument (flash tester) can record and save the measurement data in real time, and at the same time can be analyzed and compared. This provides an important basis for quality control and production process optimization, to help companies improve product quality and production efficiency.

V. Wide range of applications

Fully automated image meter (flash meter) is suitable for a variety of shapes and sizes of metal parts measurement, whether it is a simple two-dimensional dimensional measurement, or complex three-dimensional morphology measurement, can achieve accurate measurement.

Fully automatic imaging instrument (flash meter) in measuring the size of metal parts with high precision, fast, non-contact, data recording and analysis advantages, applicable to a wide range. It is believed that with the continuous progress of technology, fully automatic image meter (flash meter) will play an increasingly important role in the manufacturing industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com