The light source in the image measuring instrument plays a very important role. First of all, the light source can illuminate the workpiece, while eliminating the interference of ambient light and improving the stability and brightness of the image of the measured object. Secondly, the illumination of the light source is crucial for the clarity of the lens to capture the dimensions of the workpiece and also affects the measurement accuracy. A good light source can make the measured data more stable and accurate.

Light sources in image measuring instruments can be categorized into surface light, contour light and coaxial light types, each of which has different functions and characteristics. For example, a surface light source allows the surface of the workpiece to be uniformly illuminated, while a contour light source is used to measure through holes and contours. Coaxial light sources are used to measure highly reflective parts.

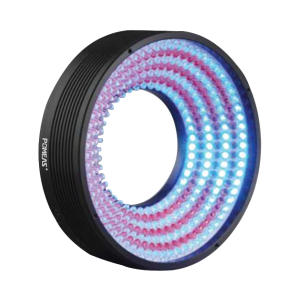

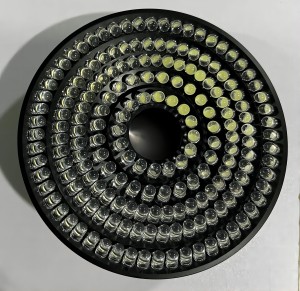

1. Surface light source: on the same side as the camera, mainly used for measuring the surface dimensions of parts, blind holes and tabs. It can make the measurement of the object in the process of being measured, all parts of the light are lighted, the light color is evenly distributed in all the edges of all the workpiece, which in turn makes the workpiece image map of any part of the shadow.

2, contour light source: usually used to measure through-hole and contour measurement, also known as the bottom light.

3、Coaxial light source: for the measurement of high reflectivity parts, round multi-angle programmable light source can easily realize the deep hole section measurement and thickness measurement.

While surface light is the most common in image measurement solutions, the use of surface light in image measurement solutions improves the accuracy, reliability and efficiency of measurements for dimensional measurement and quality control in a wide variety of industrial and scientific fields.

1, to provide uniform illumination: surface light can provide uniform illumination, so that the characteristics of the surface of the object can be clearly displayed. This helps to accurately measure the size, shape and position of the object.

2, reduce reflections and shadows: surface light can reduce reflections and shadows on the surface of the object, thus improving the accuracy of measurement. It can evenly illuminate the surface of the object and avoid measurement errors due to reflections or shadows.

3, improve contrast: appropriate surface light can improve the contrast between the object and the background, making the characteristics of the object more obvious. This helps to better recognize and measure the details of the object.

4, applicable to different materials: surface light can be applied to objects made of different materials, including metal, plastic and glass. It can provide proper illumination to accurately measure the dimensions and features of various objects.

5, flexibility and adjustability: surface light can usually adjust the brightness, color and direction of the light to suit different measurement needs. This flexibility makes surface light widely applicable in various image measurement applications.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com