Laser profile sensors are an essential tool for many industrial applications. They can be used to measure the thickness, width, and shape of objects, as well as to detect defects and irregularities.

Laser profile sensors are used in a wide variety of industrial applications, including

Quality control Laser profile sensors can be used to inspect products for defects, such as cracks, scratches, or uneven surfaces. Material handling Laser profile sensors can be used to sort objects by size, shape, or other characteristics. Robotics Laser profile sensors can be used to guide robots in performing tasks such as assembly and welding.

If you are looking for a precise and accurate way to measure the dimensions of objects or to detect defects, then a laser profile sensor is the perfect solution for you. Laser profile sensors are available in a variety of models to meet the needs of any application.

To learn more about how laser profile sensors can be used in your industry, please visit our website or contact us.

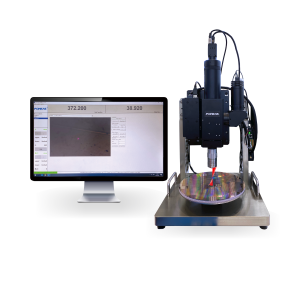

How Laser Profile Sensors Work

Laser profile sensors work by emitting a beam of light onto the object being measured. The reflected light is then collected by a sensor, which converts it into an electrical signal. This signal can then be used to determine the dimensions of the object or to detect defects.

The Basics of Laser Profile Sensors

Laser profile sensors are typically made up of the following components:

A laser source

A beam expander

A scanning mirror

A detector

A signal processing unit

The laser source emits a beam of light that is then expanded by the beam expander. The scanning mirror reflects the beam of light onto the object being measured. The detector collects the reflected light and converts it into an electrical signal. The signal processing unit then analyzes the signal and determines the dimensions of the object or detects any defects.

Advantages of Laser Profile Sensors

Laser profile sensors offer a number of advantages over traditional measurement methods, including:

Accuracy: Laser profile sensors are very accurate, and can measure objects with a high degree of precision.

Speed: Laser profile sensors are very fast, and can measure objects quickly and efficiently.

Repeatability: Laser profile sensors are very repeatable, and can produce consistent measurements over time.

Ruggedness: Laser profile sensors are rugged and reliable, and can be used in harsh environments.

Cost-effectiveness: Laser profile sensors are cost-effective, and offer a good value for the money.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com