The six fundamental parameters of machine vision optics are:

Illuminance: The amount of light that falls on the object being inspected.

Luminance: The brightness of the object being inspected.

Contrast: The difference in brightness between the object and its background.

Color: The color of the light.

Directionality: The direction from which the light is coming.

Coherency: The degree of correlation between the light waves.

The following sections will discuss each of these parameters in more detail.

Illuminance

The illuminance of a light source is measured in lux. Lux is a unit of luminous flux per unit area. The luminous flux is the total amount of light emitted by a light source, and the area is the surface area that is being illuminated.

The illuminance of a light source is important because it determines the amount of light that falls on the object being inspected. If the illuminance is too low, the object will not be visible to the machine vision system. If the illuminance is too high, it can cause glare and reflections, which can make it difficult for the machine vision system to accurately identify the object.

Luminance

The luminance of an object is measured in candelas per square meter (cd/m2). Candelas per square meter is a unit of luminous intensity per unit area. The luminous intensity is the amount of light that is emitted in a particular direction by a light source.

The luminance of an object is important because it determines how bright the object will appear to the machine vision system. If the luminance of the object is too low, it will not be visible to the machine vision system. If the luminance of the object is too high, it can cause glare and reflections, which can make it difficult for the machine vision system to accurately identify the object.

Contrast

The contrast of an object is measured as the difference in luminance between the object and its background. Contrast is important because it determines how easy it will be for the machine vision system to identify the object.

Color

The color of a light source is important because it can affect the way that objects are perceived by the machine vision system. The color of the light source can also affect the contrast of the object.

The ideal color for a machine vision application will vary depending on the specific application. However, a good rule of thumb is to use a light source that is close to the color of the object being inspected.

Directionality

The directionality of a light source is measured as the angle of the light beam. The angle of the light beam can affect the way that objects are illuminated.

Coherency

The coherency of a light source is measured as the degree of correlation between the light waves. Coherent light waves are waves that are in phase with each other. Incoherent light waves are waves that are not in phase with each other.

The coherency of a light source can affect the way that objects are perceived by the machine vision system. Coherent light can cause interference patterns, which can make it difficult for the machine vision system to accurately identify objects.

These parameters are all important to consider when choosing a light source for machine vision applications. And the right light source can help you improve the accuracy and reliability of your machine vision system. It can also help you reduce costs and increase productivity.

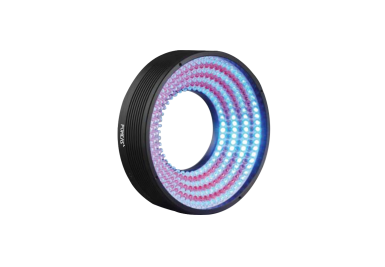

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com