Die slices are widely used in many industries such as electronics and mobile phones, where they can serve as a functional or structural aid, so the dimensional requirements for die slices are very stringent and need to be measured with precision.

Measurement needs:

Multiple die-cutting products length, width, distance and other dimensions of rapid batch inspection.

Measurement solution:

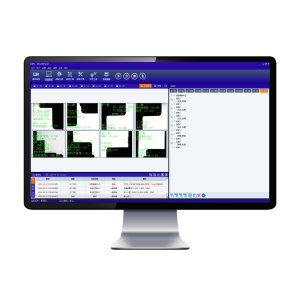

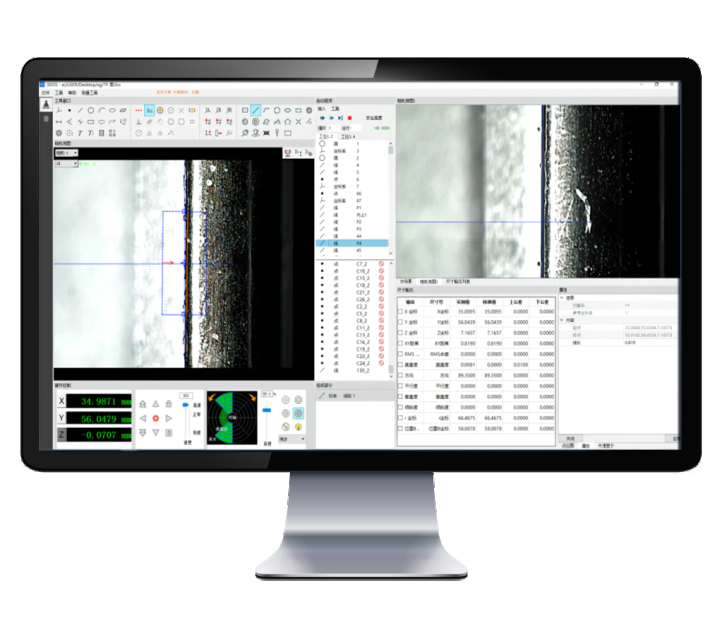

Use POMEAS IMAGE3 PRO image dimension measuring instrument, can effectively improve the measurement accuracy and efficiency of die-cutting film.

Solution Advantages:

1. Simple measurement process: Place the product on the carrier table, program it, and then start it with one key to measure it quickly, which is not difficult to operate and easy to learn and use.

2. High measurement accuracy: with self-developed double telecentric industrial lens, low distortion, high image reproduction, accurate measurement data.

3. High measuring efficiency: measuring range of 300x200, can do multiple products at the same time measurement, shorten the inspection time.

4. Intuitive inspection data: Enter the tolerance, automatically determine whether the product data is qualified or not, the results are clear at a glance. In addition, the test results can be output in a variety of formats, easy to save and view.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com