Classification of Light Sources in Machine Vision and Characteristics of Various Light Sources

In machine vision systems, the choice of light source is critical for image acquisition and processing. Artificial light source is the main light source in machine vision, which converts various forms of energy (thermal, electrical, chemical) into optical radiation. Artificial light sources are generally categorized as follows:

Thermal radiation light source

Gas discharge light source

Solid state light source

Laser

Among them, light-emitting diode (LED) light source, as a new type of semiconductor light-emitting material, has very obvious advantages in life and stability.

Here are some common types of LED light sources and their benefits:

Bar light source: LED are arranged in a straight line or combination, high illuminance, light source directivity. The lighting effect is also in line with the linear law or its superposition. Applicable to electronic component identification and defect detection, character and shape recognition.

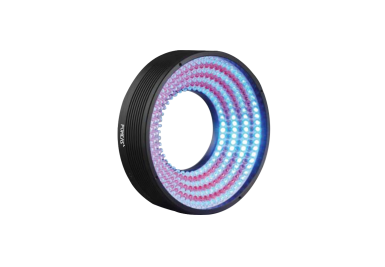

Ring light source: ring light source is divided into vertical irradiation ring light source, angle irradiation ring light source, low angle ring light source, shadowless ring light source. Suitable for plastic container inspection, workpiece screw hole positioning, label inspection, pin, integrated circuit print inspection and other similar purposes.

Back light source: use ultra-high brightness LED for frontal vertical illumination, optimized light path by special light guide material, good parallelism. Suitable for appearance inspection, or size measurement

Coaxial light source: special illumination design to achieve high uniformity. Widely used in semiconductors, PCB boards, and surface imaging inspection of metal parts, with very good uniformity, outstanding imaging of abnormal features on smooth surfaces, and good expressiveness.

Point light source: using high-power LED, color optional, small size, high luminous intensity. Can be used in combination for accent lighting or fill-in lighting.

Various types of light sources are available, and different light source designs can be used according to different requirements to achieve the best illumination imaging effect and the best detection effect.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com