Machine vision systems are changing the manufacturing industry.

In today's competitive landscape, manufacturers are looking for ways to improve efficiency, quality, and productivity. Machine vision systems can help them do just that.

Machine vision systems can automate tasks that were once done manually, such as inspecting products for defects, reading barcodes, and sorting parts. This can free up workers to focus on more important tasks, improve accuracy, and reduce costs.

If you're a manufacturer looking to improve your operations, a machine vision system could be the answer. Contact us to learn more about how machine vision can benefit your business.

Benefits of Machine Vision Systems in Manufacturing

There are many benefits to using machine vision systems in manufacturing. Here are just a few:

Improved quality: Machine vision systems can help manufacturers ensure that products are meeting quality standards.Reduce the number of defects and improve the overall quality of the product.

Reduced costs: Machine vision systems can help manufacturers reduce costs and increase profits by automating tasks and improving quality.

Automated processes: Machine vision systems can automate tasks that were once done manually, reduced labor costs and increase productivity.

Speed to market: Machine vision systems can help manufacturers bring new products to market faster. This can give manufacturers a competitive advantage in the marketplace.

Increased flexibility: Machine vision systems can help manufacturers be more flexible in their production processes.So that manufacturers can react quickly to changes in the marketplace.

Types of Machine Vision Systems

There are many different types of machine vision systems available. The type of system that is best for a particular application will depend on the specific needs of the manufacturer.

2D machine vision systems are used to inspect products for defects or to measure dimensions.

3D machine vision systems are used to create a 3D model of a product. Thus, 3D data such as segment differences, flatness, etc. of the product are obtained.

Machine vision systems with artificial intelligence (AI) are used to automate tasks that require human intelligence. These systems typically use deep learning algorithms to learn how to perform tasks such as object detection, classification, and segmentation.

Applications of Machine Vision Systems in Manufacturing

Machine vision systems can be used for a variety of applications in manufacturing. Here are just a few examples:

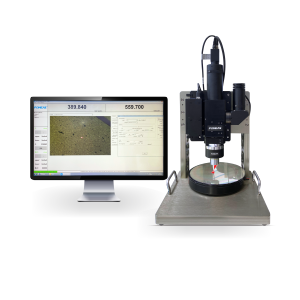

Inspection: Machine vision systems can be used to inspect products for defects or to measure dimensions, helping manufacturers ensure that products meet quality standards.

Measurement: Machine vision systems can be used to measure the dimensions of the product, quickly and accurately detecting defective products.

Alignment: Machine vision systems can be used to align parts during assembly or for print alignment.

Assembly: Machine vision systems can be used to automate the assembly of products.

Packaging: Machine vision systems can be used for product packaging to help manufacturers reduce costs and improve efficiency.

Labeling: Machine vision systems can be used to automate the labeling of products.

Machine vision systems are essential for improving productivity, quality, and efficiency in manufacturing. By automating processes, reducing costs, and improving safety, machine vision systems can help manufacturers achieve their business goals.

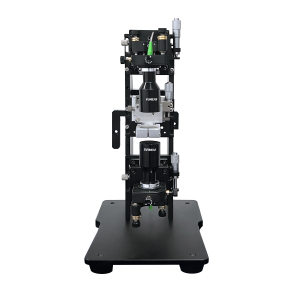

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com