In today's competitive manufacturing environment, ensuring that your products are meeting the highest quality standards is more important than ever. One of the key ways to do this is by measuring dimensions accurately.

Using dimension measurement tools and techniques, you can identify and correct defects before they reach your customers. This will help you improve product quality, reduce costs, and increase customer satisfaction.

Key Principles of Dimension Measurement

Importance of Dimension Measurement

Dimension measurement is essential for ensuring that products meet the required specifications. By measuring dimensions accurately, you can identify and correct any defects before they reach your customers. This will help you improve product quality, reduce costs, and increase customer satisfaction.

Basic Principles of Dimension Measurement

There are a few basic principles of dimension measurement that you should be aware of.

Accuracy refers to the closeness of a measurement to the true value.

Repeatability refers to the ability to obtain the same measurement multiple times.

Resolution refers to the smallest change in a measurement that can be detected.

Accuracy of Dimension Measurement

The accuracy of a dimension measurement is an important factor to consider when choosing a measuring tool.

Accuracy is even more important for critical dimensions that may affect product safety or performance, as well as dimensions that need to be consistent across the product.

When selecting a measurement tool, in addition to the application's accuracy requirements one should also consider the tool's cost, ease of use and maintenance requirements.

How to Ensure Accuracy in Dimension Measurement

There are a few things you can do to ensure accuracy in dimension measurement.

Use the correct measuring tool. Make sure that the accuracy of the tool meets your requirements.

Follow proper measuring procedures. Make sure that you are using the tool correctly and that you are following the manufacturer's instructions.

Calibrate your measuring tool regularly. Calibration ensures that the tool is accurate .

Benefits of Automated Dimension Measurement

Automated dimension measurement systems can provide a number of benefits over manual measurement methods.

Increased accuracy. Automated systems can typically provide more accurate measurements than manual methods.

Improved productivity. Automated systems can measure multiple parts at once, which can significantly improve productivity.

Reduced costs. Automated systems can help to reduce costs by reducing the need for manual measurement and rework.

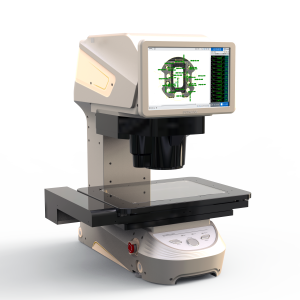

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com