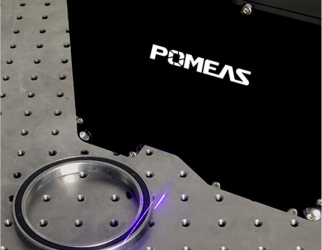

With the continuous development of science and technology, sensors are more and more widely used in various fields.3D laser profile sensor is a kind of automatic optical sensing technology used to measure distance and profile surface. It uses a line laser scanning method, which can acquire information from multiple places on the surface of an object at one time, improving the measurement efficiency. At the same time, since the line laser sensor can acquire continuous measurement data, the measurement accuracy is greatly improved.

Application areas of 3D laser profile sensor:

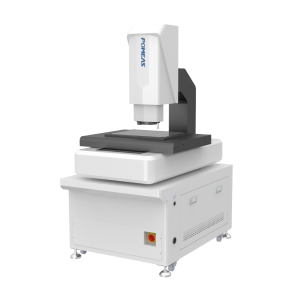

1.The laser profile sensor can be used in electronics, industry, scientific research and other fields, mainly used to measure the length, width, distance, flatness and other dimensions of the product.

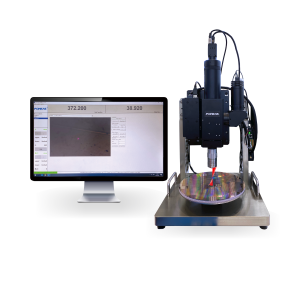

2.Laser profile sensors can also be used in new energy, automotive, aerospace and other industries for gap measurement and assembly positioning between two planes, etc.

3.3D laser profile sensors are also used in industrial automation, robotics and machine vision. It is mainly used to measure and detect objects in three dimensions. It is able to capture detailed information about the surface of the object being measured, and by combining it with back-end measurement software, it can control the production quality of the product in real time.

3D laser profile sensors offer many advantages. These include:

1. High precision: laser profile sensors can measure objects at the micron level, which is suitable for high-precision measurement application scenarios.

2. Easy to integrate: laser profile sensors are small and lightweight, and can be easily integrated with computers, robots and other equipment to achieve automated detection and data analysis.

3. Non-contact detection: the sensor detects products without contact, which can avoid mechanical pressure or damage to the measured object, thus protecting the measured object.

Laser profile sensors are used in many fields, such as the electronics industry, new energy field, automotive manufacturing and so on. They are used to fully scan objects, inspect product components, improve product quality and reduce manufacturing costs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com