In the past, the fields of artificial intelligence (AI), big data, 3D imaging and robotic process automation have made unprecedented progress. The application of machine vision technology will continue to flourish. What is the trend of the development of machine vision technology? Five directions of machine vision development are analyzed.

1. 3D Imaging and Robot Applications will continue to expand

Industrial automation is pushing factory production lines to become more intelligent, replacing manual labor and reducing labor. Machine vision has been widely used in quality control inspection, but with the emergence of integrated solutions for 3D sensor and manipulator pickup, new markets are being developed. Regardless of the position and direction of the parts, the robot pickup system can grab objects randomly. The 3D vision system can identify a large number of randomly placed parts, such as suitcases and parts boxes. Because of the dynamic processing of robots, complex objects can be selected in different directions and stacks. The combination of artificial intelligence (AI) and pick-up operation can realize parts self-selection, improve productivity and cycle time, and reduce the need for human-computer interaction in the process.

2. Increased application of in-depth learning

The advent of the 5G data network provides the ability to perform cloud computing based machine vision computing for autopilot. Massive Machine Type Communication (mMTC) allows processing large amounts of data in the cloud for machine vision applications. Deep learning algorithm using convolutional neural network classifier can quickly classify, detect and segment images. In the coming year, the development of these new AI and in-depth learning systems will increase.

3. The increase of robots

According to the International Federation of Robotics, 2018 was a record year for robot sales, with industrial robot sales growing by 31%. The trend of human cooperative robots, simplified use and process learning has helped to promote the use of robots in the field of industrial automation. In the future, industrial robots will be easier and faster to use intuitive interface programming. Man-machine collaboration will support flexible production with small batch and high complexity. Reduced complexity of use makes robots and vision systems widely used in the medium and long term.

4. Hyperspectral Imaging Analysis and Detection Technology

The next generation of modular hyperspectral imaging systems provides performance analysis of chemical materials in industrial environments. Chemical color imaging visualizes the molecular structure of the material through the result images of different colors. This allows chemical composition to be analyzed in standard machine vision software. Typical applications include the detection of plastics in meat production, the detection of different recyclable materials and the quality control of pellet inspection. The main obstacle to such systems is the amount and speed of data needed to process, but the development of faster processing, better algorithms and camera calibration still makes it a hot topic.

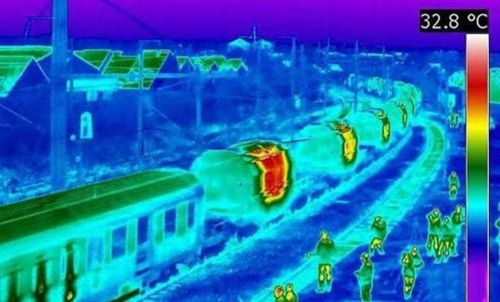

5. Thermal imaging industry testing is becoming more and more popular

Thermal imaging cameras are traditionally used for national defense, security and public safety. Thermal imaging technology is widely used in detection. For many industrial applications, such as automotive or electronic parts production, thermal data is critical. Although machine vision can see production problems, it can not detect thermal anomalies. The combination of thermal imaging and machine vision is a growing field, which enables manufacturers to detect problems that are not visible to the naked eye or standard camera systems. Thermal imaging technology provides non-contact precision temperature measurement and non-destructive detection, which is the development direction of machine vision and automation control.

Thermal imaging diagram

Thermal imaging schematic diagram

Industrial automation technology industry related to machine vision is driving more changes in manufacturing industry. Machine vision is applicable to all industries, but it is particularly important in high-specification and high-regulation industries such as food and beverage, pharmaceutical and medical equipment manufacturing. There are many reasons for enterprises turning to factory automation technology. It is difficult for enterprises to recruit workers to force enterprises to automate production lines. It is necessary to replace manual labor with machines, including improving production line efficiency, utilizing resources more effectively and improving productivity. According to speculation, it is expected that the demand of machine vision related technology in various fields will continue to deepen and grow.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com