3D GMS ProProduct Feature

High-speed mobile measurement stage

Gantry architecture movement body with high speed linear motor driven multi-axis movement stage,ensure the efficiency and stability of product measurement, a variety of stroke options, the maximum 3.6 m measuring stroke, high speed and high accuracy;

Compatible with multiple types of sensors,providing fast and strong technical support for customer needs

Multi-sensor composite application, compatible with vision, point spectrum, line spectrum, line laser, surface structured light, surface interference and other measurements of a variety of sensors, more comprehensive measurement;

lOS Platform/APP Facility

Well-designed mainstream machine vision APP for pattern recognition, localization, precision measurement and inspection of products.Adopting powerful IOS/APP system architecture to cover machine vision applications without the need to use several different software, it is convenient for customers to quickly create applications that meet users' own needs.

Fast,stable and simple vision system

Powerful data processing capabilities and patented algorithms, after years of customer on-site application, can be 7X20H stable operation.APP is easy to operate, no need for professional engineers and no need to write code programs.

Application Case

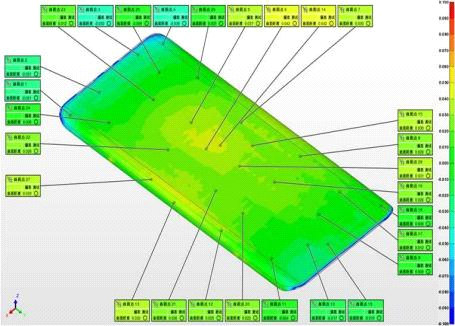

Cell Phone Frame Inspection

Inspection Item: 3D surface profile, truncated profile, etc.

Matching Program: Line laser sensor.

Equipped with a single-axis mobile platform, the line laser can acquire all the features of the product surface point cloud through mobile acquisition, and realize 3D surface profile inspection and truncated line profile inspection of the product by comparing the point cloud data with the standard data.

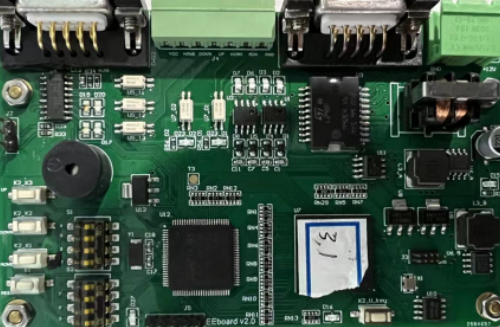

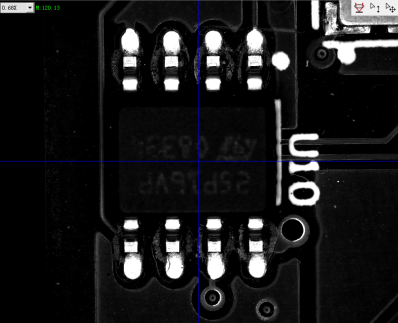

Board Card Dimension Inspection

Inspection Item: Dimensions / Roundness / Flatness / Segment Differences, etc.

Matching Program: 4K zoom high-precision measurement component (vision + point spectrum).

Quickly measure the detailed dimension of the board, especially the dimension of pins and small round holes, which can be zoomed in to obtain larger and clearer visual images.

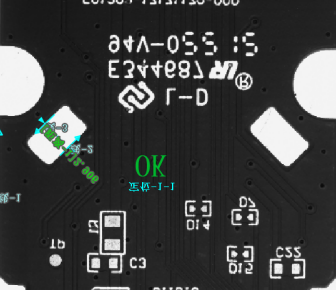

Remote Control PCB Inspection

Inspection Item: Basic dimension measurement

Matching Program: Large field of view rapid measurement components (Vision)

The dimension of the product is large and exceeds the measurement range of the field of view. Using the splicing measurement method, multiple products can be detected at the same time, and the efficiency is greatly improved.

Automotive Triangle Window Curved Glass Inspection

Inspection Item: Surface 3D Profile Inspection

Matching Program: Point Spectrum Measurement Sensor

The product is a curved surface modeling, and the scanning trajectory is determined by the profiling scanning function, which quickly acquires measurements and outputs 3D profile deviations.

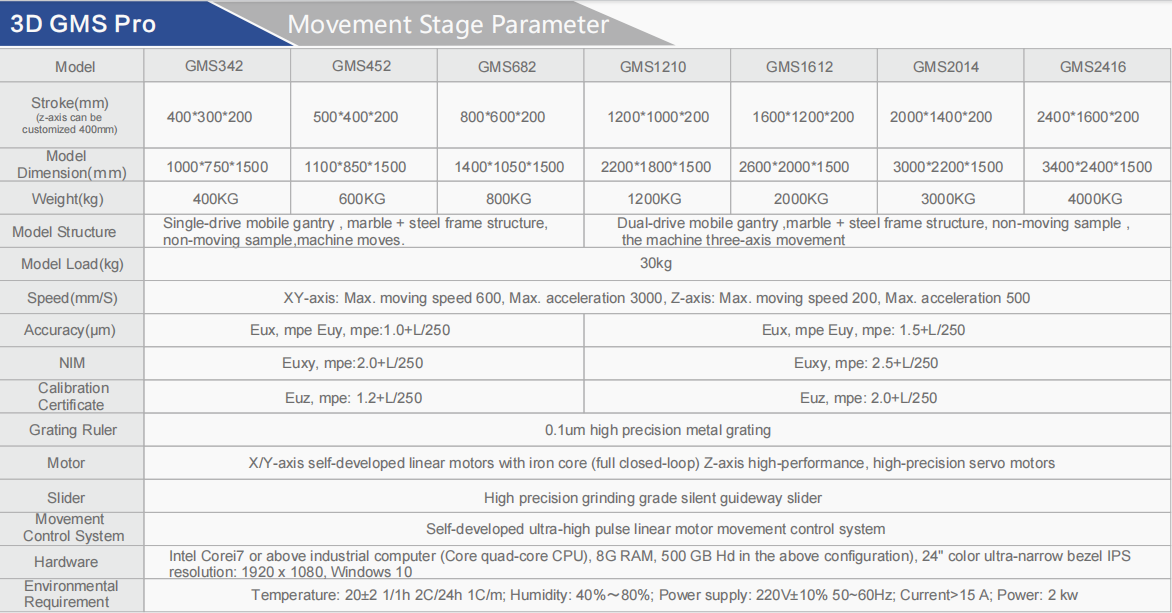

Movement Stage Parameter:

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com