How does a Telecentric Measurement System measure hardware components?

I. Preparations Before Measurement

1. Fixture Positioning and Clamping: Select appropriate fixtures based on the shape of hardware components (e.g., bolts, nuts, stamped parts) to secure workpieces on the reference surface of the measuring table, preventing displacement during measurement. For small precision hardware, utilize vacuum suction or elastic fixtures to avoid surface damage; large components require locating pins and reference blocks for precise positioning.

2. Equipment Parameter Calibration: After powering on the instrument, calibrate the measurement system using standard gauge blocks (e.g., 0.01mm precision calibration blocks) to ensure projection light intensity, sensor sensitivity, and algorithm parameters align with measurement requirements. Simultaneously inspect lens cleanliness to prevent dust from affecting projection imaging quality.

3. Measurement Parameter Preset: Based on the hardware component's measurement requirements (e.g., length, diameter, angle, aperture, profile, etc.), preset measurement items, accuracy requirements (typically supporting ±0.001mm precision), and data output formats (e.g., Excel, PDF) within the instrument control system.

II. Core Measurement Process: Projection - Imaging - Analysis - Calculation

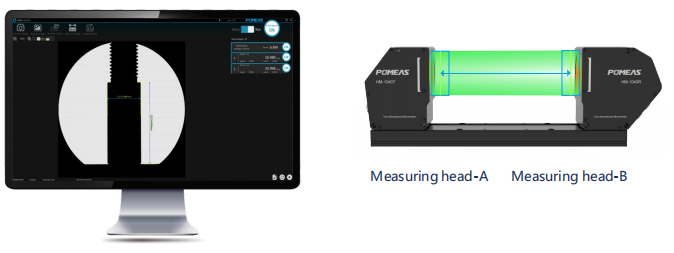

The core measurement process of the POMEAS Online Projection Dimension Measuring Instrument HM Series revolves around “projection imaging + algorithmic analysis,” with specific steps as follows:

1. Projection light illumination: The instrument incorporates a high-brightness LED projection light source (some models support multi-color light switching). Parallel light is projected onto the metal component surface via optical lenses. After transmission or reflection, the geometric features—such as contours and edges—of the hardware are clearly projected onto a high-resolution CCD sensor, forming a 2D image at a 1:1 or magnified scale relative to the workpiece. Compared to traditional projection measurement, this series employs intelligent light source adjustment technology that automatically adapts light intensity based on hardware material (e.g., metal, plastic coating), preventing imaging distortion caused by reflections or shadows.

2. Image Acquisition and Preprocessing: The sensor converts the projected image into digital signals transmitted to the instrument's image processing system. The system first performs image preprocessing, including noise reduction (filtering ambient light interference), contrast enhancement (emphasizing the difference between workpiece edges and background), and grayscale correction (ensuring uniform image brightness), laying the foundation for subsequent feature extraction.

3. Edge and Contour Feature Extraction: Based on predefined measurement algorithms (e.g., sub-pixel edge detection, contour tracking), the system automatically identifies critical features of metal components in the image:

① Edge Features: Precisely captures straight edges (e.g., sheet metal sides), curved edges (e.g., bolt head radii), and inflection points (e.g., stamped part corners) with positioning accuracy down to 0.1 pixels;

② Contour Features: Completely extracts the outer or inner contours of the workpiece (e.g., the inner wall contour of a hole), while removing interference from non-target features like burrs and scratches (achieved through threshold settings).

4. Dimension Parameter Calculation and Output: Based on the extracted feature data, the system automatically calculates various dimensional parameters using preset measurement formulas:

① Linear dimensions: Length, width, thickness, hole diameter, spacing, etc. (calculated via distances between points, parallel lines, etc.);

② Angular dimensions: Angles between planes, central angles of arcs, etc. (calculated via vector angles, contour fitting);

③ Geometric tolerances: Such as straightness, roundness, parallelism, coaxiality, etc. (calculated via contour fitting and reference comparison).

Upon completion, the instrument displays measurement results in real time (including numerical values and deviation ranges). It supports automatic data storage, generates inspection reports, and interfaces with PLC systems and SCARA robots on production lines to enable automatic sorting of non-conforming products.

III. Adaptive Advantages in Hardware Component Measurement

The POMEAS Online Projection Dimension Measuring Instrument HM Series has been specifically optimized for the characteristics of hardware components, offering enhanced adaptability:

- Compatible with multiple hardware types: Whether small precision hardware (such as screws and washers) or complex-shaped stamped and cast parts, precise measurement is achievable by adjusting projection magnification and fixture types.

- Strong anti-interference capability: Utilizes a sealed measurement optical path + anti-reflective light source design to effectively address issues like surface reflections and rough textures on hardware, preventing imaging distortion.

- Efficient inline measurement: Rapid measurement speed (0.5-2 seconds for full-dimension inspection of a single part), supports continuous batch measurement, meets high-speed production line inspection demands without manual intervention;

- Stable and reliable precision: Utilizes high-resolution sensors (up to 5 megapixels) + high-precision algorithms, maintaining long-term measurement accuracy within ±0.001mm to meet precision manufacturing requirements for hardware components.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com