With the rapid development of industry, some companies that produce industrial parts are constantly increasing the output of industrial parts. Therefore, the traditional manual inspection efficiency has become lower and lower, which cannot meet the needs of today's enterprises. Nowadays, machine vision equipment has become a popular equipment in today's industrial sectors, and surface defect detection systems are widely used in various industries.

As the collimator is a precise angle measuring instrument, the quality of the product itself will directly affect the user experience. Therefore, precise inspection of the appearance of its parts is required.

Project Requirement for Appearance Detection of Collimator Parts

——

To detect a single sample at a time, it is necessary to clearly highlight the flaws such as scratches, indentations and bruises on the product under the application unit combination of the visual solution, which is convenient for software detection.

Project Challenge

——

● The product is tapered and has a large height difference.

● The the product surface is made of high-reflective material. Under ordinary light source lighting, the shadow of the lamp will be imaged on the surface of the product, which will affect the software identification and judgment.

● Similarly, due to the problem of high reflection on the surface of the product, objects with slightly reflective nearby will be imaged and interfere with the judgment of the software.

Solution Case

——

● 500W Monochrome CMOS high-definition camera.

● For the lens, we uses a high-precision zoom telecentric lens with adjustable 0.5X-1X aperture.

● The light source is matched with a white shadowless ring light source.

● Use black light-absorbing materials (such as black flannel) around the visual solution application unit combination.

Case Demonstration

——

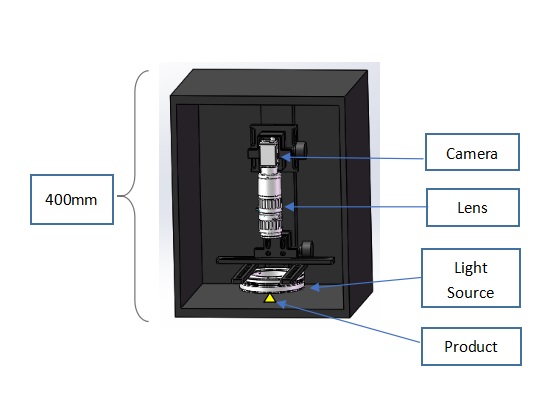

The Main Components In Detection System:

——

⑴ POMEAS 500W Monochrome CMOS high-definition camera

The new Generation of gigabit network camera with performance of low power consumption, low noise and high stability can truly restore the image in various scenes and color temperatures, maintaining clear and sharp images. It supports multiple modes such as software and hardware triggering, free running. It also support ISP functions such as sharpness, noise reduction, gamma correction, brightness, and contrast.

⑵POMEAS 0.5X-1X high resolution zoom lens: PMS-LZME-0510M

Advantage:

● Ultra-low distortion imaging based on telecentric optical path design.

● The zoom range is 0.5X-1X, and the magnification can be adjusted according to product requirements.

● The aperture is adjustable, and the depth of field and resolution can be flexibly adjusted according to use requirement. In this case, it can meet the requirement for the depth of field by adjusting the aperture.

● With high resolution, the effect is better than other zoom lenses under the same magnification

● Compact structure, it occupies a small space.

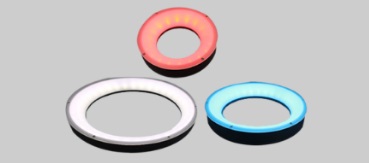

⑶ POMEAS Ring light source (high angle), parallel backlight

POMEAS has a complete of ring light source, with multi-color and multi-angle. In this case, the white shadowless ring light source is used to detect surface defects. This light source has a large irradiation area and can be used at high and low working distances. It is easy to install. With excellent uniformity light emission and without light shadow, so interference will not occur in the surface of the product.

Case Result Showing:

——

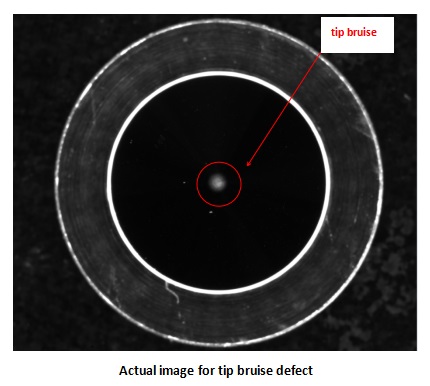

Actual image for tip bruise defect

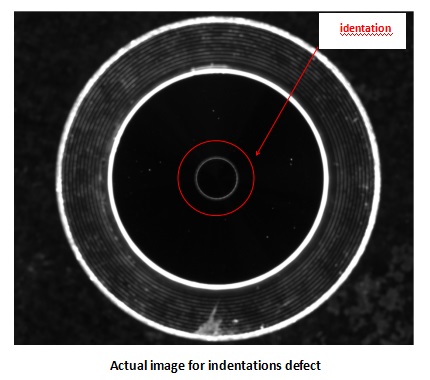

Actual image for indentations defect

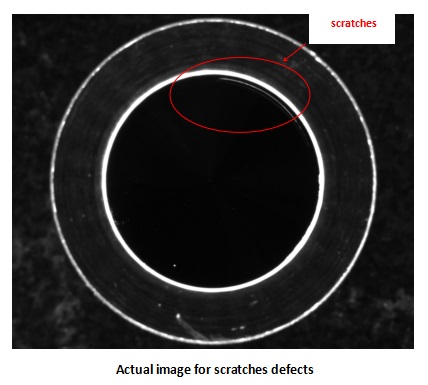

Actual image for scratches defects

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com