A Vision Inspection Scheme for The Chromatic Aberration of Solar Panels

(1)Project Background

At this stage, most of the domestic dyeing and printing enterprises rely on artificial color products for local color vision detection.The disadvantages of this method are: high misjudgment rate, mistaking the local for all; a large amount of human resources; waste of resources, high cost.Adopting the non-contact method of machine vision to detect the global color of the solar panel shading will be a good choice, and also a trend of the development of printing and dyeing enterprises.

(2)A Vision Inspection Scheme for The Chromatic Aberration of Solar Panels

POMEAS 1 MP FA LENS PMS-7528M

POMEAS GIGABIT COUNT CCO FA CAMERA

Industrial control computer : i5CPU 4G memory

Machine vision inspection software system based on POMEAS independent development

Preparation: suitable machine vision inspection scheme can be configured according to the actual environment

(3)Detection content

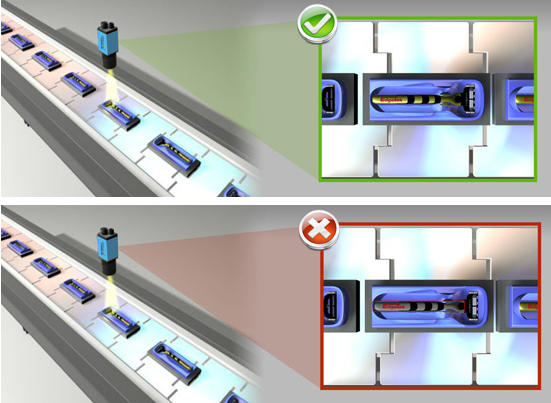

Whether the solar panel have a chromatic aberration

(4)Detection method

The industrial lens and CCD industrial camera are fixed to the top of the solar panel product, and then the image color difference value comparison processing is performed. Analyze whether the processing result is within the required range value. Unqualified alarm handling.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com