Detection Requirement

——

Characters defects recognition and soldering tin defects detection for hexahedrons of inductor or resistor products

Project Challenge

——

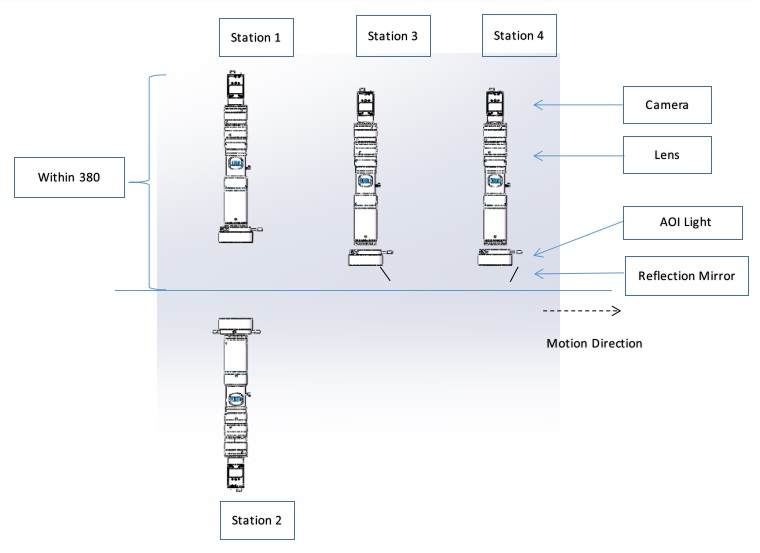

①The resistor moves in a fixed direction and cannot be turned over. The lens cannot be directly pointed to the product to do detection due to the limitation of structure, When detecting the side.

②There are many kinds of defective resistors, so it is impossible to detect all defective resistors with a single light source.

③AOI light source can detect most defects, but conventional industrial lens will occur defocus blur under RGB three-channel light source, resulting in unclear image.

Solution Case

——

①For the light source, we use multi-color and multi-angle AOI light source, which can accurately reflect the slope information of the resistance surface.

②For the lens, we use 12.5X high-precision zoom lens with a stable structure and a clear image.

③Match with the reflection mirror to improve brightness to make the picture clearer.

Case Demonstration

——

Core components Introduction

——

⑴POMEAS High-definition CCD camera

The new generation gigabit industry camera with lower power and smaller dimension, transmission speed 1000m bit/s, it is compatible with 100M Ethernet. With low power consumption, low noise, high stability, it can be real restore image and keep image clear and sharp, under various scenarios and color temperature.

⑵POMEAS 12.5X High Precision Zoom Lens

In order to meet the requirement of size accurate measurement and target rapid positioning, we use POMEAS 12.5x Continuous zoom lens

Advantage:

● 12.5X magnification ratio can meet the customer’s detection demand on various field of view

● Ultra-low defocusing amount ensures that the lens image shoting is still sharp and clear in different colors situation.

● High precision repeat positioning

● High stability. It can maintain mechanical stability under strong vibration environment

● With compact structure, the body remains the similar size with common zoom lens

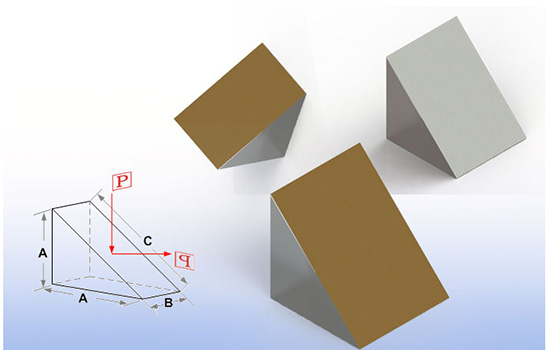

⑶Reflective Mirror

Reflect mirror as a optical components is working based on the law of reflection. According to the shape, the mirror can be divided into three kinds: plane mirror, spherical mirror and aspheric mirror ; According to the degree of reflection, it can be divided into a total reflection mirror and a semi-reflecting and semi-transmitting mirror (also known as a beam splitter). In this case, a plane mirror is used.

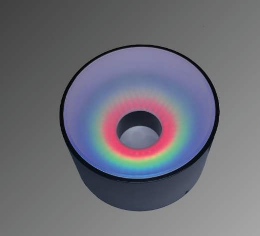

⑷ AOI vision light source

The multi-color and multi-angle strobe AOI light source can highlight the surface information of characters and solder. It has a compact structure and can be used with the controller to adjust the strobe frequency, color brightness and other parameters according to the customer's inspection requirements. In this case, this light source can be used as optional combination to detect the resistor defects such as missing parts, wrong parts, solder skips, excess solder, no solder, and reverse polarity wrong connection.

Case Result Showing:

——

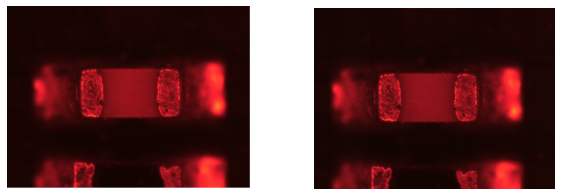

The optical ratio of the lens is 3.5X, and the resistance size is about 1mm. Focus clearly based on one of the channels, then switch to the RGB channel to observe the resistance surface effect.

Red channels actual image

( the result on Left is conventional lenses, the result on right is zoom lenses)

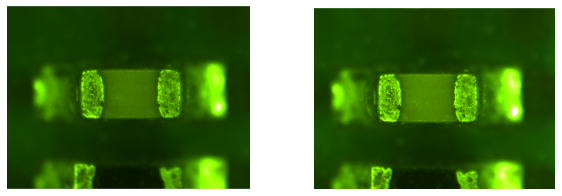

Green channels actual image

( the result on Left is conventional lenses, the result on right is zoom lenses)

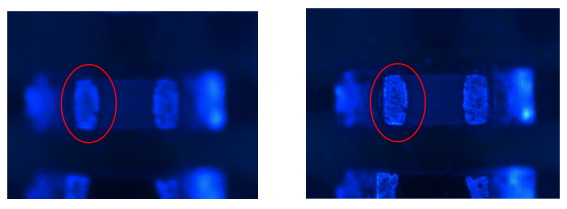

Blue channels actual image

( the result on Left is conventional lenses, the result on right is zoom lenses)

As shown above, the red channel of the light source is used to focus, then the green channel of the two lenses are clear, but the blue channel of the conventional lens obviously defocus blur, which affects the detection. However, when we use POMEAS 12.5X automatic zoom lens, it still keep the all channel image clear and meets the detection requirements.

Application Advantage in this case

——

The defocus of the RGB channel at different magnification is extremely small, which can meet the inspection demand of large and small chip resistors, inductors and other products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com