Crimp terminal is an accessory product used to realize electrical connection. With the improvement of industrial automation and stricter and more precise industrial control requirements, the demand for terminals is gradually increasing, and they are widely used in the wiring process of wires and cables in various fields and environments. The quality of the terminal can affect the quality of the energization of the wire and cable, so the quality control of the terminal in the production process is very important. The output of crimp terminal is large and the size is different. Manual inspection results in large labor intensity, easily fatigue, high rate of missed detection and high rate of false detection. So using machine vision equipment to replace human eyes on the terminal detection came into being.

Detection Demand

——

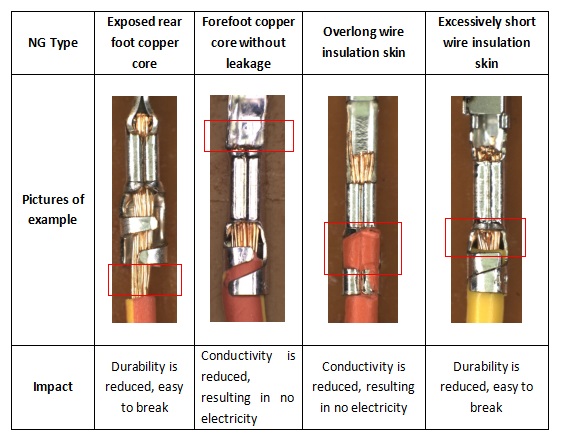

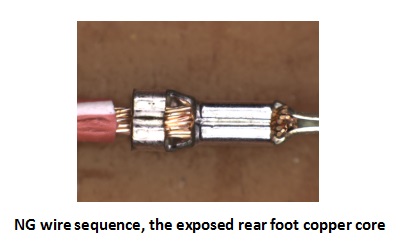

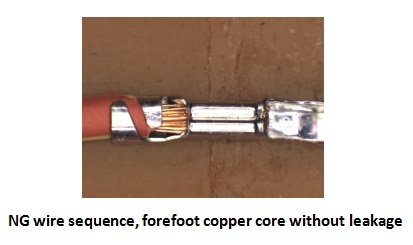

Detect the appearance of terminal crimping, and screen out bad crimping terminals, including: the overlong wire insulation skin, the exposed rear foot copper core, and the leaked forefoot copper core.

Project Challenge

——

● The wire insulation skin has various colors, so software is required to do recognition, identify multiple colors, and distinguish the colors of the copper core and the insulation skin.

● The copper core is golden, which is easy to reflect light, and a special angle light source is needed to eliminate white reflection.

● The Crimp terminal is manually placed on the jig and cannot be flattened, causing the terminal to reflect light and the color to become white, causing software misjudgment.

Solution Case

——

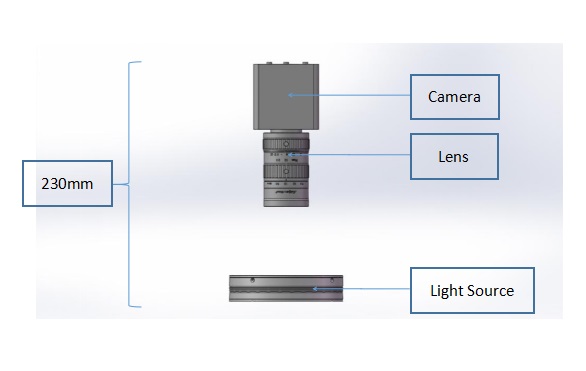

● For the camera, POMEAS intelligent detection camera is adopted into the solution.

● For the lens, POMEAS 5MP-level 75mm long focal length industrial lens is adopted into the solution.

● For the light source, POMEAS low light-emitting angle ring light source is adopted into this solution into the solution.

Case Demonstration

——

The Main Components Introduction

——

⑴ POMEAS Intelligent Detection Camera

In order to meet the visual inspection and discrimination, we use POMEAS intelligent detection camera.

Advantage:

● Low cost, the camera is directly connected to the monitor, no need to connect to the computer.

● With a wide range of detection applications, its built-in detection system includes image analysis, visual discrimination, and integration of multiple detection tools.

● The operation is simple, the built-in detection system includes an intuitive graphical interface, and the operator can just use it with the mouse.

● With high degree of color restoration, effectively reducing color distortion.

⑵POMEAS 5MP 75mm Industry Lens: PMS-75MC5M

In order to meet the needs of high-definition, long focal imaging, a 75mm industrial lens is used.

Advantage:

● High resolution, compatible with 5MP industrial cameras, suitable for industrial cameras with pixel size ≥3.45μm.

● Professional optical path design, low distortion, low dispersion imaging.

● Large depth of field, the depth of field is 5mm. Even if the core wire is not evenly clamped, it will not cause the software to be unable to capture clear images.

⑶ POMEAS White Ring Light Source

The colors of the POMEAS ring light source are red, green, blue, and whit, the light-emitting angle is 0, 30, 60, 90 degree. In this case, we use a white light source, 30 degree angle .

Advantage:

● The brightness of stroboflash is high, suitable for camera flying shooting application scenarios.

● The picture has high uniformity, reduces the white reflection on the core wire, and is convenient for software identification.

Case Result Showing:

——

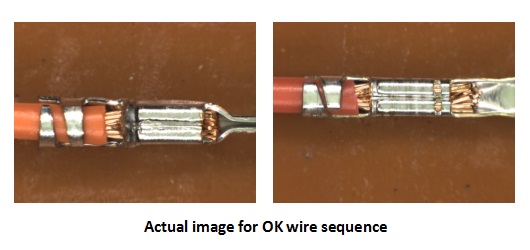

Actual image for OK wire sequence

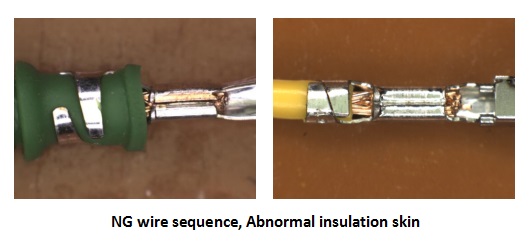

NG wire sequence, Abnormal insulation skin

NG wire sequence, the exposed rear foot copper core NG wire sequence, forefoot copper core without leakage

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com