Wire sequence detection is a step that must be done in the process of wire harness production in the wire harness factory. It is necessary to check the wire position of the wire harness, whether the arrangement is missing or incorrectly inserted, and select the defective products with the wrong hole position and different colors. The wires of different color need to be inserted into their corresponding holes in a certain order. It is an unavoidable problem to false matching wiring or wrong wire sequence by manually insert terminal wires. Identify the color sequence of the wire harness with human eyes will cause visual fatigue and lead to the outflow of defective products.

With the advancement of technology, machine vision inspection systems have gradually replaced manual visual inspection and recognition, and realized the intelligent and high-speed operation of automatically distinguishing the wiring sequence of the wiring harness.

Detection Demand

——

In order to avoid the situation that the employees on the assembly line place the core wires on the clamping fixture in the wrong order, which will affect the next core wire processing process, it is necessary to check the order of the core wires.

Project Challenge

——

● The outer diameter of the core wire is small, about Φ0.5mm, so a 5MP-level high-definition industrial lens is required for imaging observation.

● The color of some core wires is not a solid color, but a wire wound by two color wires, which can easily lead to misjudgment by the software.

● The core wire is manually placed on the jig and cannot be flattened, causing the core wire to reflect light and the color to become white, causing software misjudgment.

Solution Case

——

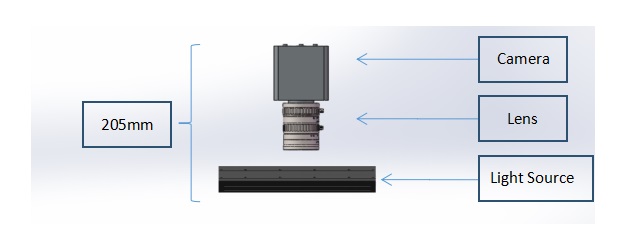

● Use POMEAS intelligent detection camera into the solution.

● Use POMEAS 5MP-level 25mm industrial lens.

● For the light source, we use bar light source into this solution.

Case Demonstration

——

The Main Components Introduction

——

⑴ POMEAS Intelligent Detection Camera

In order to meet the visual inspection and discrimination, we use POMEAS intelligent detection camera.

Advantage:

● Low cost, the camera is directly connected to the monitor, no need to connect to the computer.

● With a wide range of detection applications, its built-in detection system includes image analysis, visual discrimination, and integration of multiple detection tools.

● The operation is simple, the built-in detection system includes an intuitive graphical interface, and the operator can just use it with the mouse.

● With high degree of color restoration, effectively reducing color distortion.

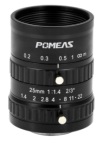

⑵POMEAS 5MP 8mm Industry Lens: PMS-25MC5M

In order to meet the needs of high-definition, wide-field imaging, a 25mm industrial lens is used.

Advantage:

1. High resolution, compatible with 5MP industrial cameras, suitable for industrial cameras with pixel size ≥3.45μm;

2. Professional optical path design, low distortion, low dispersion imaging;

3. Large depth of field, the depth of field is 5mm. Even if the core wire is not evenly clamped, it will not cause the software to be unable to capture clear images;

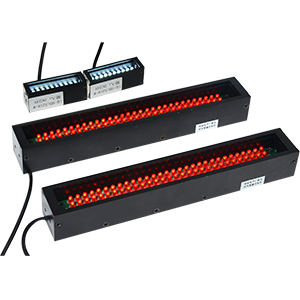

⑶ POMEAS White Bar Light Source

The colors of the POMEAS bar light source are red, green, blue, and white. In this case, we use a white light source.

Advantage:

● High flexibility, the angle of the light source can be flexibly adjusted with the mounting bracket.

● The picture has high uniformity, reduces the white reflection on the core wire, and is convenient for software identification.

Case Result Showing:

——

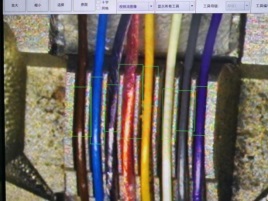

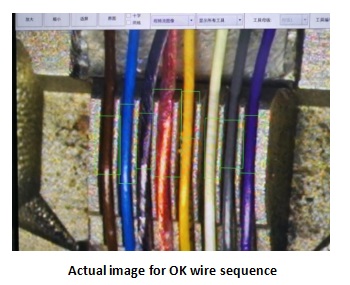

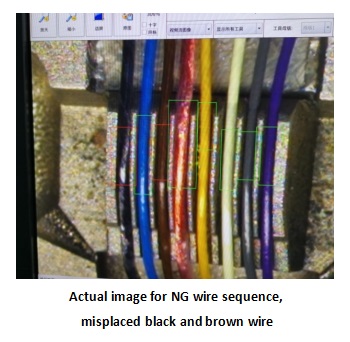

Actual image for OK wire sequence

NG wire sequence, misplaced black and gray wire

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com