IC electric component is a part of the electronic component and smaller machines&instruments, and the basic functional units of an electronic information system. In order to ensure the quality of electronic devices, strict inspection requirements are required for the IC manufacturing process. Among them, IC component defect detection includes: surface defect recognition, size inspection, silk screen clarity detection and IC inductance pin coplanarity detection, etc.

IC Inductance Pin Foot Coplanarity Detection Requirement

——

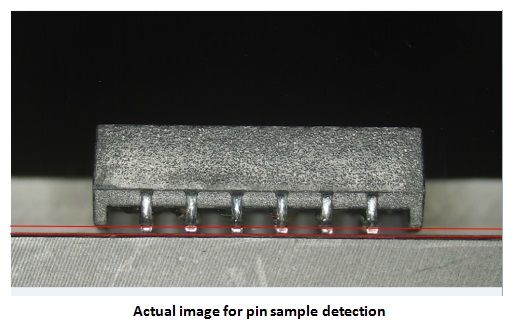

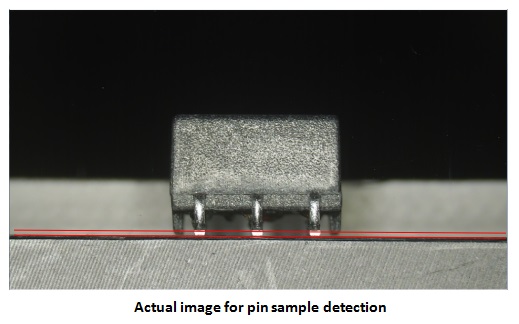

Detect the pin coplanarity of components such as transformers and so on.

Project Challenge

——

1. The vision system only can do detection from side and it is required to stay laying , when the product is placed normally.

2. There are many types of products to be detected, and the vision system needs to be able to switch magnification to be compatible with detecting products of different sizes.

Solution Case

——

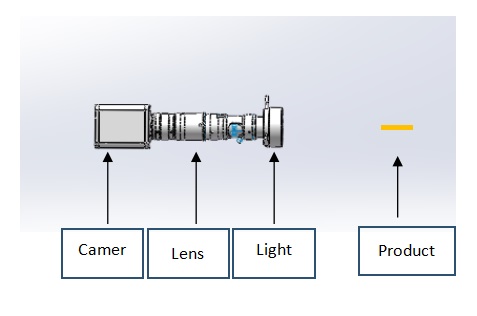

1. For the camera, we use 200W high-precision color HDMI camera.

2. For the lens, we use high-precision 6.5X manual detented zoom lens

3. For the vision illumination, we match white highlight ring illumination to this solution.

4. Use transparent glass as positioning distance

Case Demonstration

——

Core Components Introduction

——

⑴ POMEAS 200W high-definition HDMI camera

Through the high-definition photosensitive chip and high-speed processor built into the industrial camera CCD, while providing 1080P high-definition images, the frame rate and focusing speed are significantly improved. When moving to the desired observation position, the image will not have smear at all. This new observation method can greatly increase the speed of observation.

The POMEAS HDMI Camera is equipped with a cross target function, which can draw the detection area and mark the text according to the customer's needs. The operation is simple, fast and efficient. Allow new employees to work in the shortest possible time.

⑵ POMEAS high-definition zoom lens: PMS-Z65D

In order to ensure the compact structure required from the coplanarity in the detection solution to obtain high-quality images, we select PMS-Z65D detented fixed-magnification zoom lens.

Advantage:

The magnification ratio is 0.7X-4.5X, and the zoom ratio is 6.5X, which can meet the detection demand of customers for large and small different size products;

Excellent optical performance, high resolution, low distortion, which can make the image particularly clear, employees can easily see the pin end position;

With modular design, it can be flexibly matched with different accessories according to different product sizes to meet the use;

With feature of high stability, can keep clear images even with multiple zooming.

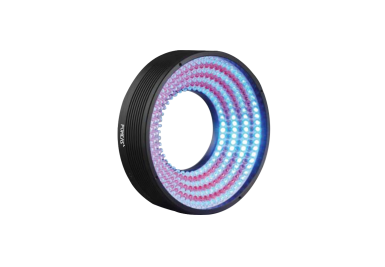

⑶ POMEAS vision illumination

POMEAS ring illumination has a complete range of ring light sources, with multi-color and multi-angle for optional. In this case, a white ring light source with high angle and small inner diameter is used. It is arranged in high-density LED, and its inner diameter is small, and it has effect of concentrated beam, and high brightness. It can clearly illuminate the end position of the pin foot to distinguish it from other areas, making employees to easily align the detection area.

Case Demonstration

——

Actual image for pin sample detection

Actual image for pin sample detection

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com