(1)Project description:

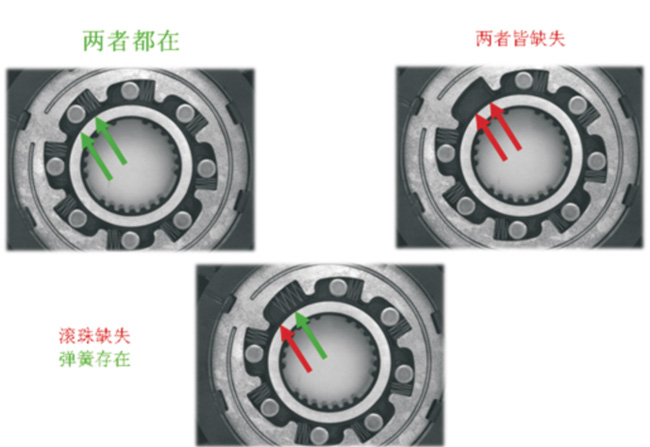

The engine flywheel is the active part of the clutch, so in the process of assembling the car, it is necessary to detect the lack of spring and ball in the clutch, and the correct installation position.

(2)Vision Inspection Solution for Clutch and Flywheel Parts

POMEAS high resolution bi-telecentric lens PMS-DTC0088-390

POMEAS 5 MP gigabit industry camera

POMEAS ring light

IPC:I5CPU 4G Memory

Machine vision inspection software system based on POMEAS independent development

(3)Vision Inspection Solution for Clutch and Flywheel Parts Descrption

For the detection of large area devices such as clutch, the image of spring and ball of the clutch is highlighted with the high resolution of the two sides and the circular light source. Due to the production line on the clutch image position in the field of view has certain uncertainty, so the first thing the image positioning technology, to the overall positioning of clutch, and then to clutch the internal testing for each station, obtain the ball and spring state.

(4)Working Effect:

Since the system is running, the normal work rate above 99.8%, the visual detection system in the process of auto parts assembly, for enterprises to save more than three stations, and greatly reduce the labor intensity of production workers and improve the reliability of the production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com