Detection Requirement

——

Automatic visual recognition detects characters flaws on chips, Including chip characters Offset,chip characters lacked ink and chip characters ink-spilling.

Project Challenge

——

● How to detect impurities such as ink stains on the chip surface? Ordinary light cannot penetrate the oil stains and can not light up the characters on the chip.

● The characters on the chip are small, about 1mm*1mm, so a high-resolution telecentric lens is required for imaging observations.

● To achieve chip identification, it needs to meet the requirements of automatic and efficient detection, and require the frequency of taking pictures is 0.3 S/PCS, so gigabit network industrial cameras are required.

Solution Case

——

● For the camera, it uses POMEAS high-speed industrial camera

● For the telecentric lens, it uses 0.17X high resolution telecentric lens

● And match with red coaxial illumination

Case Demonstration

——

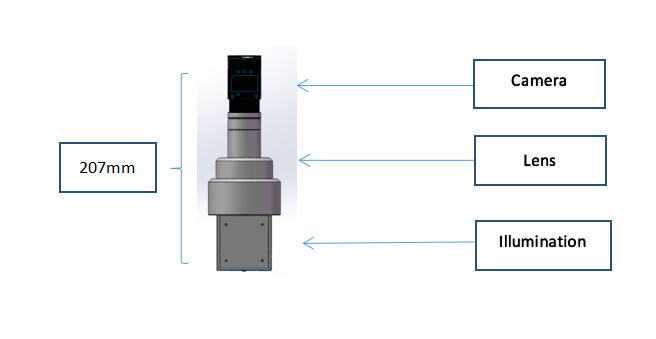

Core Components Introduction:

——

1)POMEAS High frame rate gigabit camera

In order to meet the requirements of automatic and efficient detection, we apply this POMEAS 10 megapixel industrial camera.

● High frame rate gigabit camera moving shot image in high speed, it can meet the requirements of 0.3s/pcs high-speed photo shot image recognition.

● Under high speed moving shot image, The image transmission is stable, no drop-frame, no cutout.

2)POMEAS high resolution telecentric lens: PMS-017HT110

In order to meet the requirements of characters clear imaging and defect recognition, We apply this 5MP telecentric lens with high resolution in this case.

Advantage:

● High resolution: The resolution is up to 0.016mm, so the characters can be clearly imaged and defects can be accurately recognized by the software.

● Low distortion: TV distortion is as low as 0.01%. Characters will not be distorted due to lens distortion. And then the software will not occur the judgment result to be wrong;

● Extending depth-of-field: The depth of field is 11mm. It will not cause the software unable to capture clear images, even if the chip's position changes up and down during detection.

3)POMEAS red coaxial illumination

For POMEAS external design with coaxial illumination, There are coaxial red infrared illumination, coaxial blue illumination, coaxial white illumination. In this case, we use the infrared illumination.

Advantage:

● With high penetrability, which can penetrate through the ink stain on the chip to clearly observe the characters defects.

● The image with high uniformity makes it easy to be recognized by software.

● Stroboscopic illumination with high brightness, suitable for moving shot image application scene.

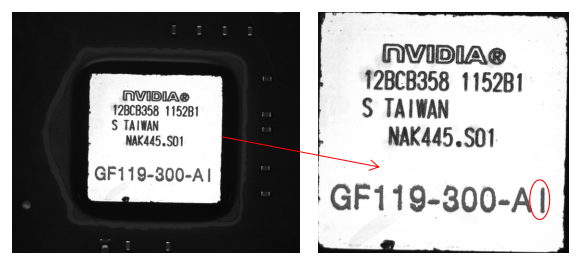

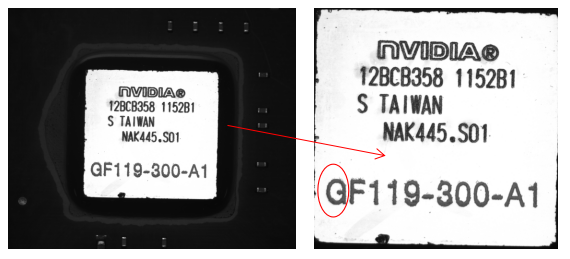

Case Result Showing:

——

Chip qualified product actual image

Chip characters lacked ink actual image

Chip characters Offset actual image

Chip characters ink-spilling actual image

Application Advantage in this case

——

● Compact structure, automatic detection can be realized by combining with the platform.

● With successful cases, POMEAS supplys one-stop purchase of vision lens and components!

● We POMEAS supply technical support and even welcome customers all over the world take the lens and the solution to do door-to-door test sample in our company. We also have free trial service!

With our core technology supporting, POMEAS has been committed to support over 1000 customers in over 30 countries to assist them to improve their Comprehensive competitive power to become a leader in industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com