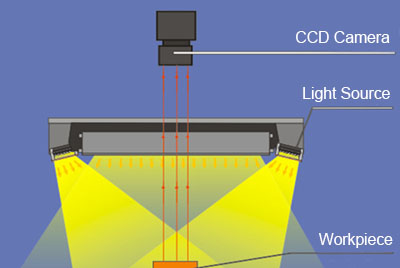

The illumination system in machine vision system is a very important part. How to choose the light source scheme has a direct impact on the image processing. Therefore, the illumination source is far from simply enhancing the brightness of the image. A good illumination system can reduce image processing time and improve the efficiency of the whole machine vision system. So how to choose the appropriate lighting system in machine vision system?

Appropriate lighting is the key to the success of machine vision applications and the first consideration. How does lighting affect machine vision applications?

When choosing a visual light source, the following five aspects should be considered:

1. Is the surface smooth or rugged?

2. Is the surface dim or bright?

3. Is the object bent or flat?

4. What is the color of the bar code or marker?

5. Detecting moving objects or stationary objects?

The following is a collection of practical examples of machine vision lighting, which will look more like it.

Case 1: Detection of cracks in glass using non-diffuse light

Objective: To detect cracks and scratches on glass containers.

Lighting Technology: Dark Field

In this application, dark field illumination is used to create a bright, easily detectable feature of interest in a dark background. Light passes directly through transparent bottles in a dark area. Most light penetrating transparent objects will not be detected by the camera. If the material is irregular, such as cracks, some light will highlight the irregularity. Especially scratches create an internal vacancy where light refracts and reflects, scattering at many angles, including back to the camera. These lights transform the hard-to-detect scratches into bright features in a dark background.

Case 2: Creating contrast with color

A useful way to create a high contrast image in machine vision applications is to illuminate objects with special wavelength (color) light. For black-and-white cameras, the wavelength of light can brighten or darken the same features as color. Use the color wheel as a reference, choose an opposite color light to darken the feature, or choose the same color light to brighten the feature. For example:

1. If you want the darkening feature to be red, use green light.

2. The use of green light can make the green features appear brighter.

3. Remember the difference between red and blue light on aluminium.

Case 3: Eliminating Reflection Using Infrared Light

Machine vision system relies on gray level transformation in digital image. In many visual applications, ambient light brings unwanted bright reflection, which makes it difficult or impossible to detect features of interest. Infrared light can solve this problem.

Case 4: Using Infrared Light to Eliminate Color Differences

Infrared light can be used to eliminate gray differences between color objects. Dark objects absorb infrared wavelengths, creating consistency, while others show shadows. The illumination scheme is helpful to detect the inconsistency of color or shadow changes.

How to choose a suitable lighting scheme for your machine vision system needs to be considered from many aspects. It can be applied to your own vision scheme according to the actual situation. I believe that it will achieve twice the result with half the effort!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com