Machine vision system generally consists of light source, lens, industrial camera, image processing unit, communication input and output units. As a key component of machine vision system, the most essential function of industrial camera is to convert the optical signal into the ordered electrical signal of small hd industrial camera. However, cameras have different classification methods according to chip type, interface type, scanning mode, resolution size, output signal mode, output color, output signal speed and response frequency range.

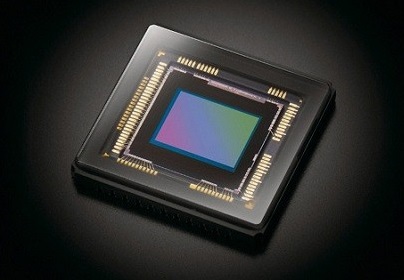

According to chip types, industrial cameras can be divided into CCD cameras and CMOS cameras. The main difference between CCD cameras and CMOS cameras lies in the way of converting light into electrical signals. For CCD cameras, light shines on the pixel and the pixel generates electric charge. For CMOS, each pixel completes the charge-to-voltage conversion by itself and generates digital signals at the same time.

Industrial cameras can be divided into a variety of interface types, including USB interface, GIGE gigabit interface, HDMI interface, Camera Link and VGA interface, etc. All kinds of interfaces have advantages and disadvantages, and can be selected according to their own needs.

Industrial cameras also have a variety of categories, according to the scanning mode can be divided into interlaced scanning cameras, progressive scanning cameras; According to the resolution size, it can be divided into ordinary resolution camera and high resolution camera. According to the output signal can be divided into analog camera, digital camera; Pomeas has a wide range of industrial cameras available for your reference.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com