I. Advantages of Spectral Confocal Sensors

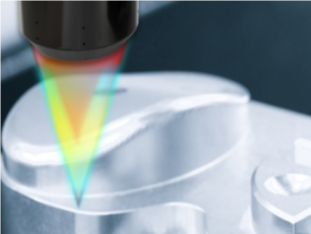

Spectral confocal technology achieves sub-micron (or even nanometer) axial distance measurement by analyzing the focal positions of light at different wavelengths on an object's surface.

1. Non-contact measurement: Prevents damage to soft or delicate surfaces caused by contact probes, particularly suitable for coating layers on smartphone frames and thin-walled structures of precision injection-molded parts.

2. High precision and speed: Theoretical accuracy reaches the nanometer level, with stable ±0.1μm repeatability achievable in industrial applications. Paired with high-speed scanning mechanisms (e.g., galvanometers or linear motors), single-point measurement speeds can reach thousands of measurements per second.

3. Strong Interference Resistance: Insensitive to surface tilt angles and reflectivity variations, enabling stable detection on highly transparent (e.g., glass), highly reflective (e.g., metal), or low-reflectivity (e.g., black injection-molded parts) materials.

4. Multi-Parameter Simultaneous Measurement: A single scan captures multidimensional data including dimensions, step height, flatness, and roughness, minimizing errors from repeated clamping.

II. Integrated Solutions: Collaborative Optimization of Hardware and Software

1. Hardware Integration: Multi-Sensor Array and Motion Control

-

Multi-probe Collaborative Measurement: For complex curved surfaces in smartphone midframes (e.g., R corners, arcs), a multi-spectral confocal probe array is employed. Through optimized spatial layout, it achieves full-dimension coverage of the inspection area. For instance, POMEAS spectral confocal sensors can simultaneously measure midframe edges, hole positions, and curved surface step differences, eliminating blind spots inherent in single-probe scanning.

-

High-Speed Scanning Mechanism: An integrated scanning platform driven by linear motors or galvanometers enables simultaneous X-Y-Z axis motion, boosting inspection efficiency. For instance, POMEAS fully automated image measuring machines paired with high-resolution industrial cameras (10-megapixel class) can scan detailed features of small injection-molded parts within a 100×75mm² field of view, completing full-dimension inspection with a single setup.

-

Compact Design: For micro-sized precision injection-molded parts (e.g., earphone housings), utilizes miniaturized spectral confocal probes (e.g., POMEAS SFS series) combined with micro-fixtures and background marker stitching technology to achieve full-dimension inspection without marking points.

2. Software Integration: AI Algorithms and Automated Workflows

-

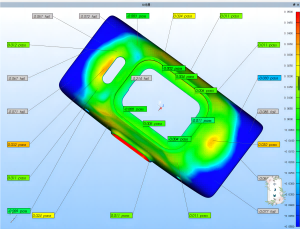

Intelligent Feature Extraction: Equipped with AI deep learning algorithms, it automatically identifies blurred boundaries, multiple edges, and burr interference in smartphone frames, extracting critical dimensions (such as aperture and margin) and step features (like step height and gap values).

-

One-Click Operation and Automated Reporting: Using professional measurement software (e.g., IMAGE series), users simply place the workpiece and launch the program. The system automatically completes focusing, scanning, data analysis, and report generation. For instance, IMAGE series flash measurement instruments support CAD drawing import and template matching, measuring 5,000 locations within 3 seconds. Reports are available in PDF/CSV formats for direct integration with production management systems.

-

Multi-Parameter Statistical Analysis: The software incorporates a Statistical Process Control (SPC) module that monitors dimensional and step distribution patterns in real time (e.g., CpK values, trend charts) to alert for production anomalies. For instance, POMEAS spectral confocal sensors can integrate with machine vision technology to simultaneously analyze parameters like coating thickness and surface roughness, optimizing process parameters.

III. Typical Application Scenarios and Case Studies

1. Mobile Phone Mid-Frame Inspection;

2. Precision Injection-Molded Parts Inspection;

3. 3D Curved Glass Inspection。

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com