Application of Spectral Confocal Displacement Sensors in Image Measurement Vision Solutions

In the fields of precision manufacturing and industrial automation, optical measurement solutions leverage high-precision imaging and intelligent analysis technologies to achieve non-contact measurement of object parameters such as dimensions, morphology, and defects. As the core optical measurement component, spectral confocal displacement sensors serve as a critical technological pillar within optical measurement systems. This is due to their sub-micron accuracy, non-contact measurement capability, and adaptability to complex materials.

I. Application Scenarios: Addressing Precision Measurement Needs Across Multiple Industries

1. Semiconductor and Electronics Manufacturing

- Wafer Surface Topography Inspection: Measures micron-level protrusions, depressions, and warpage on wafer surfaces with a detection accuracy of 0.006 microns, ensuring chip packaging flatness.

- Micro-Component Dimension Verification: Performs non-contact measurement of 0.1mm-level micro-components' position and dimensions during electronic assembly, preventing damage to fragile components caused by contact probes.

- Transparent Material Thickness Measurement: Utilizes double-reflector spectroscopy to precisely measure glass substrates and optical film thicknesses, with error controlled within ±0.005mm.

2. Precision Machinery and Optical Processing

- Turbine Disc Profile Inspection: Utilizing a 2D nano-positioning device equipped with a spectral confocal sensor, this system enables online inspection of complex turbine disc surfaces with profile error ≤5 microns.

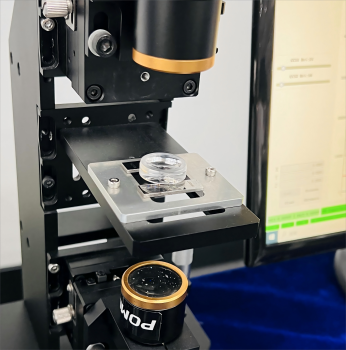

- Optical Lens Center Thickness Measurement: Performs single-point thickness and curvature measurements on lenses with a diameter of 69mm and thickness ranging from 1 to 4mm. The inspection speed of 20 seconds per piece meets the demands of large-scale production.

- Surface Roughness Analysis: Measures the surface roughness of diaphragm gas meter valve covers using a non-contact focusing method, achieving a U95 uncertainty of 13.9%, replacing the traditional contact stylus method.

3. Automotive and Aerospace

- Engine Cylinder Block Geometric Inspection: Measure surface roughness and critical hole dimensions to ensure sealing integrity and wear resistance.

- Windshield Thickness and Geometric Profile Measurement: Achieve nanometer-level precision in detecting gaps between glass panels and metal chassis to prevent cracking risks caused by assembly stresses.

- Composite Material Defect Detection: Non-destructive inspection of internal defects such as delamination and voids in carbon fiber reinforced composites (CFRP) to enhance structural safety.

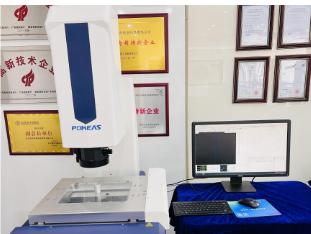

III. System Integration: Collaborative Optimization with Industrial Vision Cameras

The integration of spectral confocal displacement sensors with industrial vision cameras achieves deep synergy between measurement and imaging through coaxial arrangement and synchronized control:

- Coaxial optical path design: The sensor probe and camera lens are mounted coaxially to ensure the measurement optical path aligns with the imaging optical path, eliminating parallax errors.

- Intelligent focus adjustment: Based on distance data measured by the sensor, the camera adjusts the lens position via autofocus algorithms to ensure image clarity.

- Data Fusion Analysis: High-precision displacement data from the sensor is combined with texture and color information captured by the camera. Through deep learning algorithms, this enables defect classification (e.g., scratches, stains, cracks).

IV. Core Advantages: Driving the Advancement of Image Measurement Technology

1. Sub-micron precision: Axial resolution of 0.006 microns meets ultra-precise measurement demands in semiconductor, optical, and other industries.

2. Non-contact measurement: Prevents damage to soft, fragile materials caused by contact probes, suitable for specialized applications like artifact restoration and biological tissue measurement.

3. Material Universality: Delivers stable measurements across metals, glass, plastics, ceramics, and surfaces with high reflectivity, transparency, or roughness, overcoming limitations of traditional sensors.

4. High-Speed Dynamic Response: Supports sampling frequencies up to 10kHz for real-time inspection on high-speed production lines.

5. Environmental Adaptability: Maintains stable performance in industrial environments with temperatures ranging from -10°C to 60°C and vibration acceleration ≤5g, reducing reliance on specialized environments like cleanrooms.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com