In precision manufacturing scenarios such as nanoscale packaging of semiconductor chips, micrometer-level contour control of aircraft engine turbine disks, and millimeter-level curvature calibration of curved displays, traditional contact measurement tools are increasingly inadequate due to issues like pressure deformation and speed lag. Meanwhile, laser triangulation sensors are limited by their insufficient adaptability to complex surfaces and transparent materials.

Spectral confocal displacement sensors have emerged as a breakthrough technology for overcoming precision measurement bottlenecks, leveraging three core advantages: non-contact operation, sub-micron accuracy, and universal material compatibility. Functioning as the “optical eye” of the industrial sector, these sensors integrate spectral encoding with confocal imaging to achieve a transformative leap from ‘visible’ to “accurate measurement” in high-end manufacturing fields such as microelectronics, optical processing, and aerospace. This advancement redefines the technical boundaries of precision measurement.

Application Case:

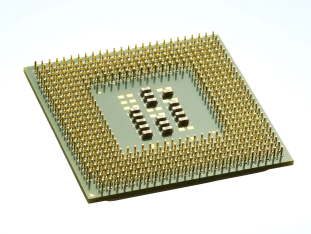

1. Microelectronics and Semiconductor Manufacturing

- Wafer Thickness and Warpage Inspection: During semiconductor packaging, the sensor measures wafer thickness via single-side measurement with axial resolution of 0.006 micrometers. It detects warpage errors ≤5 micrometers to ensure chip flatness.

- Camera Module Travel Measurement: To accommodate complex materials within the module such as glass lenses and metal barrels, the sensor employs multi-wavelength light sources (e.g., blue, green, red light) tailored to different reflective properties. This prevents signal loss and ensures continuous travel data. For instance, Zero Vision's CL series sensors achieve precise control over camera focus and zoom parameters through 3-nanometer repeatability accuracy and a 32kHz sampling rate.

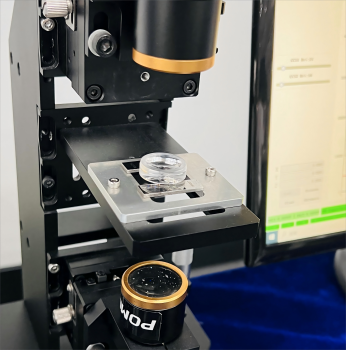

2. Optical Component Processing

- Lens Thickness and Curvature Measurement: Utilizing spectral confocal technology, the sensor measures lenses with a diameter of 69mm and thickness ranging from 1 to 4mm on a single side. With a detection speed of 20 seconds per lens, it meets mass production demands while achieving an accuracy of 5 micrometers.

- Surface Topography Analysis: When integrated into a 3D scanning system, the sensor provides 2D and 3D topography data for detecting defects such as scratches and dents on lens surfaces.

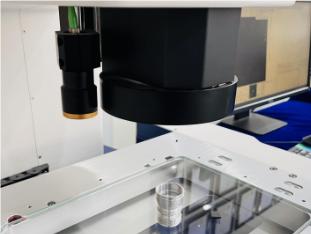

3. Precision Machining

- Turbine Disc Profile Inspection: Equipped with a sensor featuring a 2D nano-positioning device, enabling online inspection of complex turbine disc surfaces with profile error ≤5 microns.

- Deep Hole and Blind Hole Measurement: For deep holes with a diameter of 3mm, the sensor employs a coaxial optical path design, achieving a spot size as small as Φ6μm. It can penetrate deep into the hole for measurement, with a repeatability deviation of only 0.018mm.

4. Processing of Transparent Materials

- Glass Thickness Measurement: The sensor measures thickness by penetrating the front and rear surfaces of transparent materials without contacting the workpiece, eliminating measurement errors caused by angle limitations in traditional laser sensors. For instance, in windshield inspection, the sensor achieves nanometer-level precision to ensure assembly safety.

- Film Thickness Control: In the production of laminated water-cooled plates, sensors detect variations in the 130μm transparent film layer thickness using a 12μm spot size and anti-interference algorithms. Repeatability deviation is ≤0.6μm, meeting the accuracy requirement of ≤3μm.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com