Five Compelling Reasons to Choose Laser Autofocus Microscope Systems

In the fields of precision manufacturing and high-end inspection, the accuracy, efficiency, and safety of microscopic observation directly determine product quality and production efficiency. Laser autofocus microscopic systems, leveraging their five core advantages—non-contact operation, high precision, high speed, strong adaptability, and digitalization—have become the preferred inspection equipment for high-end industries such as semiconductors and 3C electronics.

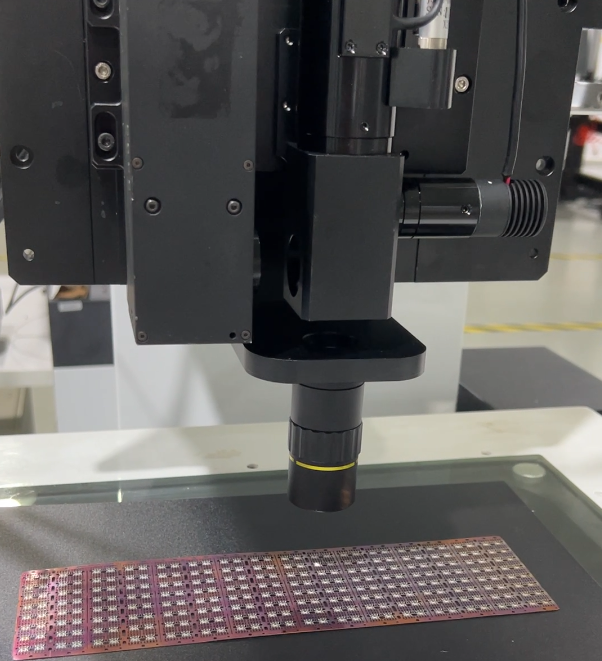

I. Non-contact Microscopic Observation: Preserving Sample Integrity and Avoiding Damage Risks

Traditional contact-based microscopic observation often causes physical damage such as scratches and indentations to fragile samples—including semiconductor wafers, precision components in 3C products, and flexible materials—compromising sample integrity and testing accuracy.

The laser autofocus microscopy system employs a non-contact observation mode, achieving focusing and observation through laser signals without any contact with the sample surface throughout the process. This feature not only maximizes sample preservation—making it particularly suitable for inspecting high-value, fragile precision samples—but also eliminates detection errors caused by probe wear in contact-based observation. It extends equipment lifespan and reduces maintenance costs.

II. High-Precision Microscopic Observation: 0.5μm-level positioning accuracy, controlling minute variations.

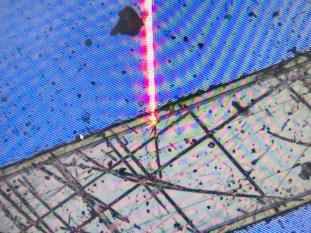

The inspection demands of precision industries impose extremely high accuracy requirements on microscopic systems. Laser autofocus microscopic systems achieve high-precision observation at the 0.5μm level through advanced laser positioning technology. This precision enables the accurate capture of minute surface imperfections, dimensional deviations, and microscopic structural details—such as circuit patterns on semiconductor chips or minute solder joints in 3C products—providing a more accurate representation of the sample's true condition compared to traditional microscopy systems.

Whether for wafer defect inspection in the semiconductor industry, component dimensional calibration in the 3C sector, or other high-precision inspection scenarios, these systems precisely control minute variations. They provide reliable data support for quality assessment, helping enterprises enhance product yield rates.

III. High-Speed Real-Time Focusing: ≤0.4s rapid response for enhanced detection efficiency

In mass production inspection scenarios, inspection efficiency directly impacts production cycle times. Laser autofocus microscopy systems feature rapid real-time focusing capabilities of ≤0.4 seconds, significantly reducing single-sample inspection time compared to manual focusing or slow autofocusing in traditional microscopy systems. Even when handling batch continuous inspection tasks, they enable swift focus switching without prolonged waiting periods, effectively boosting inspection efficiency to meet the demands of large-scale mass production. Additionally, this rapid focusing capability minimizes missed or false detections caused by focusing delays, ensuring the continuity and stability of the inspection process.

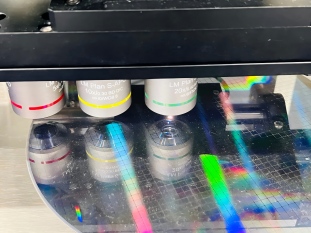

IV. Strong Adaptability: Compatible with diverse samples across multiple industries, breaking scene limitations.

Different industries and sample types demand varying microscopic observation environments and parameters. The laser autofocus microscopy system offers exceptional adaptability, effortlessly meeting inspection requirements across multiple sectors including semiconductors, 3C electronics, automotive electronics, and precision machinery. Whether examining samples made of metal, plastic, glass, or other materials—or dealing with flat surfaces, curved surfaces, or irregular shapes—the system achieves stable focusing and clear observation through intelligent parameter adjustment. There is no need to configure dedicated microscopy equipment for different samples, reducing corporate equipment investment costs, improving equipment utilization rates, and meeting diverse inspection requirements.

V. Digital Technology Empowerment: Data-Driven Statistical Analysis to Support Intelligent Decision-Making

The laser autofocus microscopic system integrates advanced digital technology, overcoming the limitations of traditional microscopic observation that was “visual only and difficult to quantify.” The system automatically collects various data during the observation process (such as defect counts, dimensional data, and location information), and features data statistics, analysis, and export capabilities. Through digital processing, inspection data gains enhanced objectivity and traceability, enabling enterprises to conduct batch analysis and trend forecasting of results. This provides data support for optimizing production processes and upgrading quality control systems. Additionally, digital operations facilitate automated integration of inspection workflows, aligning with smart factory production inspection systems and driving the intelligent transformation of inspection processes.

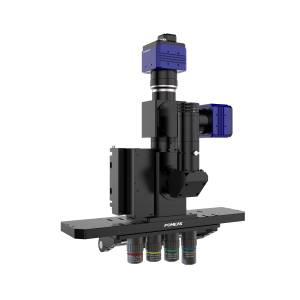

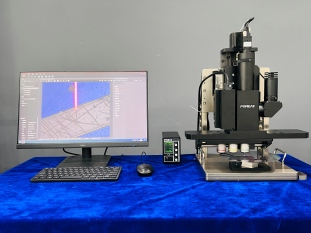

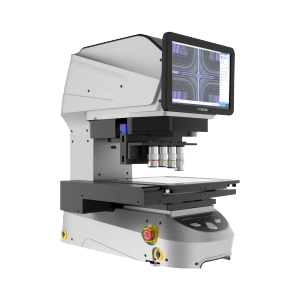

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com