How to perform full-size precision measurement of tablet components in 10s?

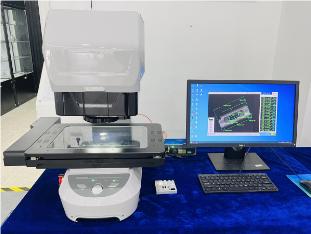

In the tablet manufacturing industry, component precision directly impacts overall product performance and user experience. From the precise alignment of charging ports to the responsive operation of power buttons, dimensional deviations in even the smallest parts can trigger quality issues. Achieving efficient and accurate component measurement has become a critical challenge in production. POMEAS's high-precision IMAGE 3 MAX image measuring system delivers an innovative solution for tablet component inspection through its exceptional measurement capabilities and intelligent operation.

I. Core Challenges in Tablet Component Measurement

Tablet computer components feature complex structures, minute dimensions, and diverse materials. Traditional measurement methods such as calipers and projectors suffer from three major limitations:

1. Inefficient: Manual point-by-point measurement is time-consuming and cannot meet the demands of large-scale production.

2. Inaccurate: Micron-level errors are difficult to detect, impacting assembly yield rates.

3. Data lag: Manual recording is prone to errors and cannot provide real-time feedback for production adjustments.

Take charging ports as an example: pin spacing tolerances must be controlled within ±0.02mm, a standard that traditional methods struggle to achieve consistently. Power button travel tolerances are even more stringent, with any deviation potentially causing operational lag. These challenges have compelled the industry to seek more advanced measurement technologies.

II. IMAGE 3 MAX's Technological Breakthrough: Three-in-One Measurement System

POMEAS IMAGE 3 MAX employs multi-sensor fusion technology to deliver a comprehensive measurement solution covering 2D/2.5D/3D applications:

1. 3D Profile Scanning: Millimeter-Level Modeling Capability

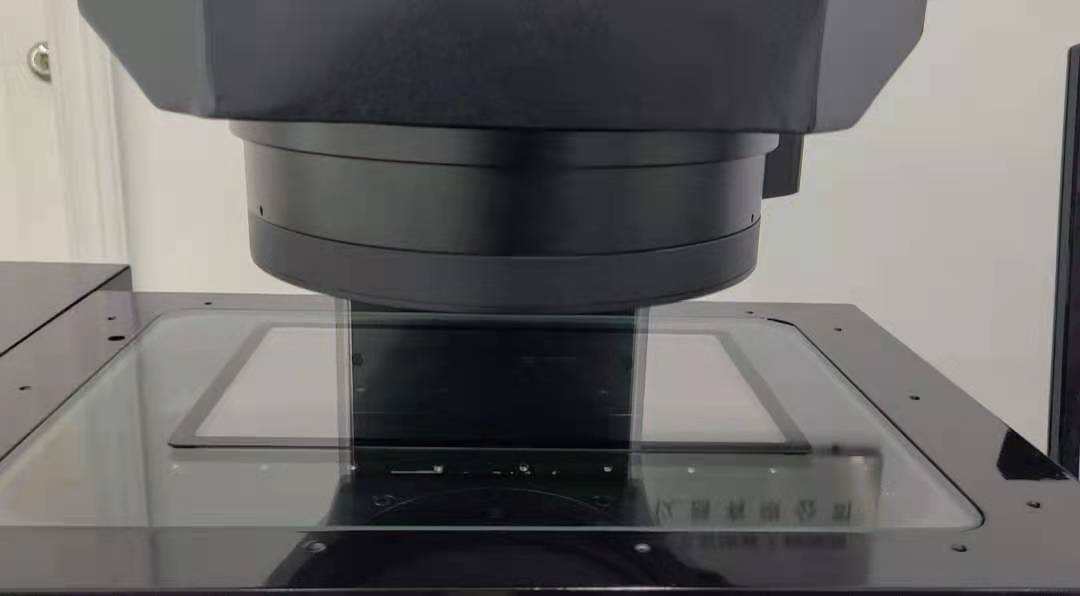

By integrating high-resolution industrial cameras with laser displacement sensors, it rapidly generates 3D point cloud data for parts. For complex structures like curved housings and heat dissipation holes, the system automatically performs feature extraction and dimensional annotation with measurement accuracy reaching ±0.005mm. Actual testing shows scanning a tablet back cover takes only 10 seconds with over 98% data completeness.

2. Precision Flatness Inspection: Nanometer-Level Surface Analysis

Equipped with a proprietary laser interferometer module, the system performs full-area deformation detection on planar components like touchscreens and mid-frames. It automatically identifies minute warping down to 0.001mm and generates heatmaps to visually highlight deformed areas.

3. 2D Dimension Measurement: Intelligent Feature Recognition

For flat components like buttons and interfaces, the system employs AI edge detection algorithms to automatically recognize over 20 feature types including circles, rectangles, and irregular shapes. Its one-click measurement function simultaneously inspects 50 critical dimensions, maintaining repeatability accuracy within ±0.003mm.

III. Analysis of Typical Application Scenarios

Scenario 1: Comprehensive Charging Port Inspection Solution

Following the introduction of IMAGE 3 MAX, online inspection of charging ports has been achieved. The system can simultaneously measure:

Pin Pitch (Critical Dimension);Insertion/Extraction Force Test Position Depth;Anti-misalignment Slot Width;Overall Flatness.

Scenario 2: Power Button Lifespan Test

By pairing with dedicated fixtures, the system can continuously record changes in key travel:

Initial travel: 1.2±0.05mm;After 100,000 presses: 1.18±0.06mm;Real-time visualization of deformation trends;This solution enabled the client to extend the key press lifespan standard from 50,000 to 200,000 presses, significantly enhancing product competitiveness.

IV. Four Core Advantages Set the Industry Standard

-

Non-destructive testing technology: Non-contact measurement prevents scratching of precision surfaces, particularly suitable for sensitive materials like gold plating and ceramics

-

Intelligent programming system: Automatically generates measurement paths via CAD import, reducing new part import time by 80%

-

Big Data Analytics Platform: Built-in SPC statistical module traces millions of measurement data points, enabling dynamic optimization of production parameters

-

Compatibility Design: Seamlessly integrates with robotic arms and conveyor belts for effortless automation line deployment

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com