Autofocus Microscope: Comprehensive Analysis of Key Features and Application Scenarios

In modern scientific research and industrial inspection, efficiency and precision remain perpetual priorities. Traditional microscopes often face limitations in handling high-volume, demanding observation tasks due to the inefficiency of manual focusing and reliance on operator expertise. Autofocus microscopes serve as automated visual inspection tools that integrate intelligent focusing, high-definition imaging, and data analysis, significantly enhancing observation efficiency and accuracy.

I. What is an Autofocus Microscope?

An autofocus microscope is an advanced microscopic device that integrates precision optical systems with computer vision algorithms.

Its core operating principle involves the system rapidly scanning height information across the sample surface via sensors or evaluating image sharpness in real time through image algorithms. Driven by control software, high-precision motors automatically adjust the position of the objective lens or stage, instantly locating optimal focus to deliver consistently clear images. This fully automated process requires no manual intervention, enabling “one-touch focusing” or “real-time tracking focus.”

II. What are the main features?

-

Smart Auto Focus: This is its core functionality. Whether examining uneven surfaces or multiple points at varying heights during batch inspections, it achieves rapid and precise focusing, ensuring consistent image clarity across every capture.

-

High-Definition Digital Imaging: Equipped with a high-performance camera, it displays high-definition images directly on the computer screen. This facilitates simultaneous observation, discussion, and measurement by multiple users, eliminating the limitations of traditional eyepiece-based single-view observation.

-

Seamless Multi-Magnification Observation: An electric objective turret automatically switches between different magnification objectives under software control. Combined with motorized zoom functionality, it enables rapid, continuous observation from low to high magnification.

-

Powerful Data Recording and Analysis:

-

Image Capture and Recording: Easily save images of key fields of view and dynamic processes.

-

Measurement and Annotation: Perform quantitative measurements such as length, angle, area, and particle counting directly on digital images.

-

Report Generation: Automatically integrate measurement data, annotation information, and images to generate standardized inspection reports.

-

III. Core Advantages and Features

-

Ultimate Efficiency, Enhanced Productivity: Automates the cumbersome manual focusing process, making it particularly suitable for batch sample inspection. Work efficiency can be increased by several to dozens of times.

-

Objective Precision, Reliable Results: Eliminates focusing variations caused by different operators' experience and subjective judgment, ensuring consistent inspection standards and repeatable, traceable data.

-

Lowered operational barriers, freeing up manpower: Operators can begin work without extensive training, significantly reducing reliance on skilled personnel and alleviating visual fatigue.

-

Digital and intelligent workflow: All images and data are stored digitally for easy management, sharing, and secondary analysis, serving as a key tool for achieving “digital” transformation in laboratories and factories.

IV. What scenarios does it apply to?

-

Industrial Manufacturing and Precision Inspection:

-

PCB/AOI Inspection: Examines solder joint quality, circuit defects, and alignment accuracy on printed circuit boards.

-

Component Dimensional Measurement: Performs dimensional tolerance measurements on precision hardware, injection-molded parts, connectors, and similar components.

-

Surface Defect Analysis: Detects scratches, stains, particles, corrosion, and other imperfections on metal, glass, and semiconductor wafer surfaces.

-

-

Biomedical and Life Sciences:

-

Cell and Tissue Observation: Enables routine examination and digital archiving of histological sections and cell cultures.

-

Drug Development and Screening: Automatically focuses and analyzes cellular responses in microtiter plates during high-throughput screening experiments.

-

-

Materials Science and R&D:

-

Cross-section Analysis: Observing metallographic structures and grain sizes in metals, ceramics, and composite materials.

-

Coating and Film Inspection: Measuring coating thickness, examining film uniformity, and analyzing surface topography.

-

Failure Analysis: Conducting microscopic morphology observations on fractured or worn components to determine failure causes.

-

-

Academic Research and Education:

-

University laboratories: Providing stable, high-performance observation tools for scientific research, particularly in studies requiring the processing of large sample volumes.

-

Teaching Demonstration: Project microscopic images onto a large screen in real time to facilitate instructor explanations and group learning among students.

-

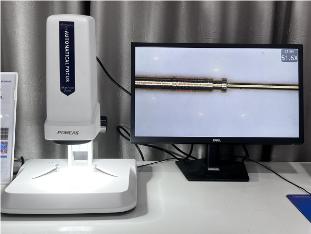

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com