Testing Background

In pharmaceutical manufacturing, pill quality control is paramount. Even minor surface defects such as bubbles, scratches, or uneven coating can lead to serious consequences.

1. Air bubbles may alter the internal structure of the drug, affecting its release rate and preventing precise therapeutic efficacy;

2. Scratches not only compromise the pill's appearance but may also prematurely expose active ingredients, reducing stability;

3. Uneven coating directly interferes with the drug's disintegration and absorption within the body, lowering patient compliance.

Testing Plan

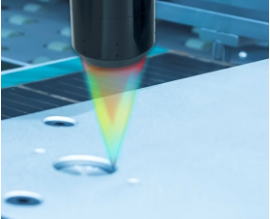

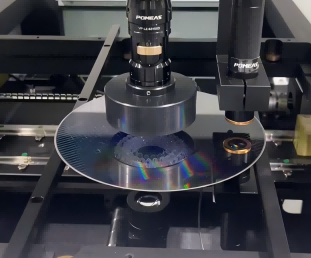

The POMEAS Spectral Confocal Displacement Sensor SFS Series operates based on the principle of spectral confocal imaging. Light of different wavelengths focuses at varying heights during propagation due to differences in refractive properties. This sensor leverages this characteristic by emitting composite light containing multiple wavelengths onto the pill surface. When light contacts the pill surface, the spectral intensity distribution reflected from defect-free areas differs markedly from that reflected from areas with defects such as bubbles or scratches. The sensor's built-in high-sensitivity spectral analyzer rapidly captures this reflected light. Through complex algorithms, it precisely analyzes the spectral intensity distribution to accurately pinpoint defect location, shape, and depth. For example, if a bubble exists on the pill surface, light undergoes special reflection and refraction at the bubble-pill interface. This causes abnormal intensity at specific wavelengths in the reflected spectrum. The algorithm rapidly pinpoints the bubble's location and precisely measures its diameter, depth, and other parameters.

1. Non-destructive inspection: Traditional contact-based measurements, such as probe measurements, can easily cause physical damage when sliding across pill surfaces, compromising pill integrity and affecting product quality. The SFS series employs non-contact inspection, maintaining a safe distance between the sensor and pills. Information is obtained solely through light interaction, eliminating any form of mechanical contact and ensuring each pill remains completely unaffected after inspection.

2. Multi-wavelength fusion technology. Tablet coatings are often transparent or translucent, posing significant detection challenges. The SFS series sensor ingeniously leverages the focusing characteristics of different wavelengths: short-wavelength light with high energy and low penetration is ideal for detecting shallow surface defects; long-wavelength light with low energy and strong penetration penetrates deep into the coating layer to detect hidden flaws. By integrating information from multiple wavelengths, defect detection rates are significantly enhanced—even micron-level bubbles beneath the coating become detectable. Experimental data shows that multi-wavelength fusion technology improves coating defect detection rates by over 30% compared to single-wavelength detection.

3. Data Visualization: When connected to specialized analysis software, the sensor converts detection data into intuitive 3D defect models. These models realistically display the entire tablet surface in three dimensions, with different defects marked by distinct colors and shapes. Key parameters like depth and area are clearly annotated. Manufacturers can leverage these models to rapidly identify production process vulnerabilities. For instance, upon detecting uneven coating issues, they can precisely adjust parameters such as spray pressure, temperature, and rotation speed of the coating equipment. This approach reduces defect occurrence at the source and enhances product quality stability.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com