I. Overview of the Plan

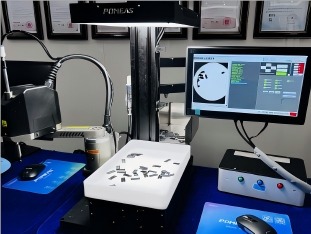

This solution combines a Telecentric Measurement System with a SCARA robotic arm to achieve efficient, precise dimensional measurement and rapid sorting of small components such as metal rings. Designed for automated quality inspection and classification on production lines, it significantly enhances production efficiency and product quality control standards.

II. Plan Components

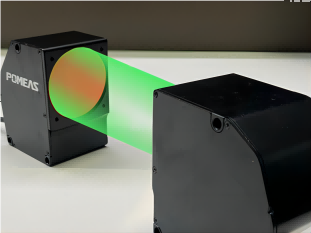

1. Telecentric Measurement System Features:

① High-precision measurement: Utilizes advanced image processing technology to ensure measurement accuracy.

② Multi-specification support: Pre-programmed for multiple product specifications, automatically identifies and measures items of varying dimensions.

③ Rapid response: Acquires product dimensions within an extremely short timeframe (e.g., within 1 second).

2. Features of SCARA Compact Robotic Arms:

① Flexible Operation: Features high-speed, high-precision motion capabilities, suitable for desktop-scale work environments.

② Rapid Grasping and Placement: Capable of swiftly grasping, moving, and placing metal rings within minimal time.

③ Intelligent Sorting: Accurately positions products into corresponding specification trays based on dimensional feedback from measuring instruments.

III. Workflow

1. Loading Stage: The SCARA robotic arm picks up a metal ring from the raw material tray. The robotic arm precisely places the metal ring onto the measurement platform of the Telecentric Measurement System.

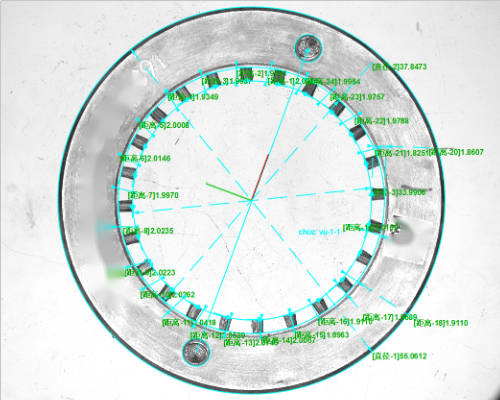

2. Dimension Measurement Stage: The Telecentric Measurement System automatically initiates the measurement program to inspect the dimensions of the metal ring. Measurement is completed within 1 second, and the dimensional data is fed back to the SCARA robotic arm's control system.

3. Sorting Stage: After receiving measurement data, the SCARA robot arm determines the appropriate specification tray for each metal ring based on predefined classification criteria. The robot swiftly picks up the measured metal ring and transfers it to the corresponding specification tray. The entire sorting process—from measurement to placement—takes no more than 3 seconds, achieving highly efficient sorting.

IV. Advantages of the Plan

1. High Efficiency: Combining rapid measurement with intelligent sorting significantly shortens production cycles and boosts productivity.

2. Precision: Utilizing high-accuracy measuring instruments and intelligent robotic arms ensures dimensional measurement accuracy and sorting correctness.

3. Flexibility: Supports multiple product specifications with easy adjustment and scalability to adapt to diverse production requirements.

4. High Automation Level: Reduces manual intervention, lowers labor intensity, and enhances the automation level of production lines.

V. Case Results

Benchtop dimensional sorting solutions are widely used in production lines for small components across industries such as electronics, automotive, and precision machinery. They are particularly suitable for scenarios demanding high dimensional accuracy and large production batches.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com