Application of Super Depth-of-Field Microscopy Solutions in Electronic Component Leads

Background of the Proposal

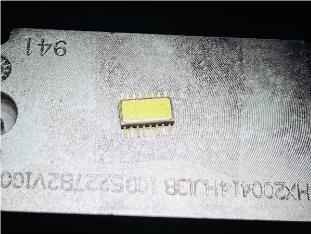

Electronic component leads (such as IC chip pins, connector pins, etc.) feature extremely small dimensions (typically 0.1-1mm in diameter, with pitch as low as 0.3mm or less), intricate structures (e.g., plating edges, bending angles, tip curvature), and pronounced three-dimensional features (e.g., height differences, perpendicularity, surface irregularities). Traditional optical microscopes, constrained by their limited depth of field (only a few micrometers to tens of micrometers), struggle to simultaneously capture the entire three-dimensional contour of pins with clarity, posing challenges for inspection tasks such as detecting plating defects, dimensional deviations, and deformations.

Solution:

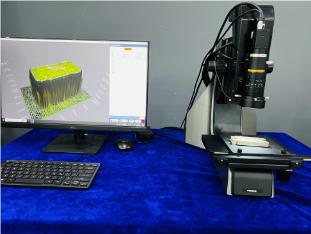

The Super Depth-of-Field Microscopy Solution comprises both hardware and software systems, which work together to achieve high-precision three-dimensional observation and measurement of pins:

1. Hardware System: Ensures clear imaging and detailed capture

(1) POMEAS 1X Telecentric Zoom Lens: The telecentric design eliminates perspective distortion, ensuring unbiased dimensional measurements across different pin locations (e.g., base and tip). The zoom function supports detail magnification at 1X magnification (expandable to higher magnifications), precisely capturing pin microstructures (e.g., plating cracks, pin burrs).

(2) High-Definition Color Industrial Camera: High resolution (typically over one million pixels) combined with color imaging clearly reproduces color variations on the pin surface (e.g., oxidation discoloration of plating) and texture features (e.g., scratches, pinholes), providing intuitive evidence for defect identification.

(3) Ring Light: Surrounding illumination uniformly lights the pin surface, eliminating shadow interference caused by cylindrical or irregular pin shapes. It is particularly effective at suppressing reflections from pin sides, ensuring sharp edge imaging.

2. Software System: Enabling 3D Reconstruction and Quantitative Analysis

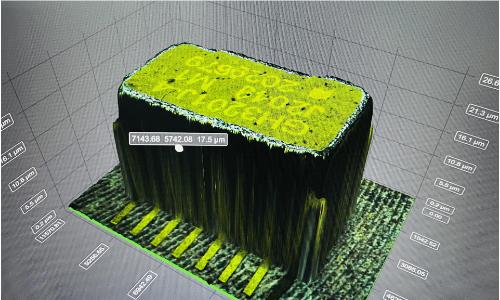

(1)POMEAS's proprietary Micro Vision3D ultra-depth-of-field microscopy software: Utilizing multi-focus image fusion technology, it overcomes the depth-of-field limitations of traditional microscopes. The software automatically captures clear images at different pin height planes, then synthesizes them through algorithms into a single, full-depth-of-field, high-definition 3D contour map. This fully reveals the pin's three-dimensional form (e.g., height, tilt angle, protrusions/indentations). Simultaneously supports dimensional measurement capabilities, enabling direct annotation and calculation of key parameters (e.g., pin diameter, pitch, perpendicularity, tip radius of curvature) directly on the 3D image.

Case Study Images

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com