What factors should be considered when selecting an online projection measuring instrument?

Against the backdrop of rapid advancements in modern manufacturing toward high precision, high efficiency, and automation, online projection measuring instruments serve as critical equipment for controlling product quality and enhancing production efficiency. The appropriateness of their selection directly impacts the smoothness of production processes and the stability of product quality. Therefore, when selecting an online projection measuring instrument, decisions should not be made based solely on individual parameters or price. Instead, a comprehensive and meticulous evaluation across multiple dimensions—including hardware performance, software functionality, and automation integration capabilities—is essential. This ensures the chosen equipment precisely aligns with actual production requirements, thereby safeguarding the production process.

I. Hardware Analysis

1. Measurement Range and Resolution

The measurement range must fully match the actual dimensions of the workpiece to be measured. Both the maximum and minimum dimensions of the workpiece should be thoroughly considered to ensure the equipment can completely cover the measurement area. Additionally, a 10%-20% operational margin should be reserved to prevent measurement failures due to workpiece dimensional deviations. Resolution determines measurement precision. High-resolution equipment captures finer details of workpiece features. For measuring precision components like electronic components or miniature hardware, a high-resolution camera is essential. For standard parts, select a resolution that balances accuracy and cost based on specific requirements.

2. Accuracy and Repeatability

Accuracy is the core metric for evaluating a measuring instrument's precision, determining how closely the measurement result aligns with the true value. In industries with extremely high accuracy requirements, such as aerospace and automotive component manufacturing, equipment achieving micrometer-level precision is typically necessary. Repeatability reflects the consistency of measurement results under identical conditions. Lower repeatability error enhances the reliability of measurement data. Typically, repeatability error must be controlled within a narrow range—such as ±0.001mm—to ensure measurement stability during mass production.

3. Measurement Speed and Efficiency

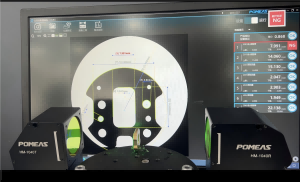

In continuous production line operations, measurement speed directly impacts overall production efficiency. If measurement speed is too slow, it can easily become a bottleneck in the production line. High-quality Telecentric Measurement System achieves rapid image acquisition and data computation by optimizing hardware architecture—such as employing high-performance image sensors and high-speed data transmission modules—combined with efficient image processing algorithms. This reduces the time per measurement, ensuring the instrument keeps pace with the production line's cycle time and minimizing the dwell time of workpieces during the measurement process.

II. Software Analysis

As the “brain” of the online projection measuring instrument, the software handles data acquisition, analysis, processing, and transmission. Its functionality directly impacts measurement efficiency and the extraction of data value. When selecting software, evaluate it based on the following dimensions:

1. Measuring Programming Efficiency

Efficient measurement programming can significantly reduce preparation time, particularly for standardized workpieces in batch production. Premium software should feature an intuitive, user-friendly programming interface supporting multiple methods like graphical programming and automatic programming. Operators need no complex programming knowledge—simply drag, drop, and click to rapidly create measurement programs. Additionally, the software enables saving measurement templates. When measuring identical workpieces later, templates can be directly recalled, eliminating repetitive programming and boosting efficiency.

2. Analytical Functions and Tools

Rich analytical functions and tools enable users to deeply interpret measurement data and promptly identify issues in the production process. The software should possess the capability to calculate various measurement parameters, such as dimensional deviations, geometric tolerances, and surface roughness. It should also perform statistical analysis of data, generating trend charts, histograms, and other visualizations to clearly demonstrate data patterns, helping users determine whether production processes are stable. When measurement data exceeds preset tolerance limits, the software promptly issues alerts to notify personnel to take corrective actions, preventing defective products from advancing to subsequent processes.

3. Data Integration and Connectivity

In the construction of smart factories, measurement data must seamlessly integrate with other production line systems to achieve comprehensive control throughout the manufacturing process. The software should support multiple data interfaces and communication protocols, such as USB, Ethernet, and RS-485, enabling data exchange with the factory's MES system, PLC controllers, ERP system, and other components. Measurement data should be automatically transmitted to relevant systems, facilitating real-time data sharing and centralized management. This provides data support for production scheduling, quality traceability, and process optimization, forming a closed-loop “measurement-analysis-control” system.

III. Automation Integration Capabilities: Adapting to Smart Production Line Upgrade Requirements

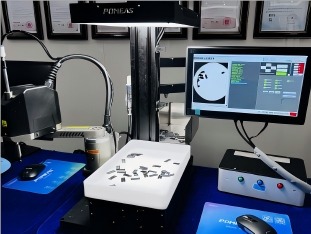

The equipment should feature a compact structural design with a small footprint, occupying minimal space for flexible installation at various points along the production line. It should seamlessly integrate into both space-constrained small-scale production lines and complex large-scale production layouts without disrupting existing workflow paths. Simultaneously, the equipment must possess robust automation capabilities, supporting seamless integration with robotic arms, conveyor belts, and other machinery. This enables automated functions such as loading/unloading, auto-focusing, and measurement—eliminating manual intervention, reducing human error, and enhancing measurement efficiency and consistency. Furthermore, the equipment can automatically adjust its measurement rhythm based on production line cadence and commands, ensuring high-level coordination with production processes. This empowers production lines to achieve comprehensive intelligent upgrades.

Selecting an online projection measuring instrument is a systematic process where hardware, software, and automation integration capabilities are mutually reinforcing and equally indispensable. Only by comprehensively evaluating all factors—including production scale, workpiece characteristics, precision requirements, and automation development plans—can the most suitable equipment be chosen. Proper selection not only ensures product quality and enhances production efficiency but also reduces long-term operational costs for enterprises. This enables businesses to gain a competitive edge in the market and drives their high-quality development.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com