Hardware Analysis of Image Measurement Instruments - Industrial Cameras

In the field of precision manufacturing, dimensional measurement accuracy directly impacts product quality and performance. With the advent of Industry 4.0, traditional contact measurement methods struggle to meet modern manufacturing's dual demands for efficiency and precision. The POMEAS Image3 series image dimension measuring instruments set a new technological benchmark in industrial measurement with their innovative dual-camera system design. Equipped with dual 20-megapixel industrial cameras and a dedicated optical system, they achieve comprehensive precision measurement from macro contours to microscopic details through an innovative “wide-field-of-view + high-precision” dual-mode design.

Image3 Series Dual-Camera Design Concept for Image Dimension Measuring Instruments (Flash Measurement Instruments)

The POMEAS Image3 series image dimension measuring instruments represent the cutting-edge of current industrial vision measurement technology. Their unique product positioning resolves the longstanding technical dilemma in traditional measurement equipment: the inability to simultaneously achieve both a wide field of view and high precision. In industries such as precision manufacturing, electronic components, jewelry processing, and tool inspection, measurement requirements often present a dichotomy: on one hand, capturing the overall contours of large workpieces is necessary, while on the other, micron-level precision measurements of critical areas are demanded. Conventional equipment, constrained by single-camera architectures, inevitably compromises between these demands. The Image3 Series delivers a perfect solution through its innovative dual-camera system.

The design philosophy of dual-camera synergy is embedded in every hardware detail. The series features two 20-megapixel high-definition industrial cameras, not merely redundant components but specifically optimized for diverse measurement scenarios. Compared to conventional models, this configuration not only doubles the effective pixel count but, more importantly, achieves a qualitative leap in measurement accuracy and efficiency through pixel-level collaboration. In the jewelry manufacturing industry, this design has proven effective in overcoming challenges posed by precious metal reflections and the multiple refractive surfaces of gemstones. In the field of tool measurement, it enables rapid detection of micron-level defects on cutting edges.

From a technological evolution perspective, the Image3 series' dual-camera design marks a significant shift in image measurement technology—transitioning from “single-function” to “scenario-adaptive.” The built-in intelligent recognition system automatically selects the optimal imaging mode based on the target object's dimensions, complexity, and precision requirements. This adaptive capability not only lowers the technical barrier for operators but also significantly enhances inspection efficiency by optimizing measurement paths. In today's industrial environment, where product processes grow increasingly complex and production cycles accelerate, the Image3 series' dual-camera system is redefining the standards for high-precision dimensional measurement.

Technical Specifications of the Image Dimension Measuring Instrument (Flash Measurement Instrument) with 20-Megapixel Industrial Camera

The dual 20-megapixel industrial cameras at the heart of the Pumis Image3 series deliver its high-precision measurement capabilities. These cameras utilize advanced CMOS sensor technology, offering a high resolution of 5472×3648 with individual pixels as fine as 2.4μm×2.4μm. This combination of large sensor size and high resolution ensures the camera fully exploits the optical lens's resolution potential, avoiding the “bottleneck effect” where lens resolution is wasted by low-pixel sensors. In terms of performance, these high-pixel industrial cameras achieve a capture frame rate of 6fps, a dynamic range up to 65.5dB, and a signal-to-noise ratio of 41.5dB—parameters that collectively form the foundation for high-quality imaging.

The relationship between pixel count and precision is critical in industrial measurement. According to optical measurement principles, system resolution = pixel size / optical magnification. Taking the high-precision mode of the Image3 series as an example, when using a 25mm diameter dedicated camera with a telecentric lens of appropriate magnification, its theoretical pixel accuracy can reach below 1μm. This means the system can clearly identify and accurately measure features as small as 1/70th the diameter of a human hair (approximately 70μm). It's important to note that actual measurement accuracy is influenced by multiple factors, including lens quality, lighting conditions, and algorithmic processing. This is why POMEAS employs a fully integrated, self-developed opto-mechanical-electronic system to ensure optimal matching across all components.

Compared to traditional 5-10 megapixel industrial cameras, the 20-megapixel camera demonstrates significant advantages in edge detection capability. When measuring complex contours or minute edges, the rich image detail provided by the high-resolution camera significantly reduces algorithmic interpolation errors. For instance, in gear pitch measurement, the transition zone between the tooth crest and root often spans only tens of pixels in width. High-resolution imaging enables more precise localization of these critical points, avoiding the “step effect” caused by insufficient pixels in traditional measurements. Leveraging this advantage, the Image3 series excels in inspecting components with stringent geometric tolerance requirements, such as gears and precision bearings.

Dual-Mode Measurement System: Intelligent Switching Mechanism for Wide Field of View and High Precision

The most innovative design feature of the POMEAS Image3 series image dimension measuring instrument is its switchable dual-camera configuration. This system integrates a φ100mm wide-field camera and a 25mm diameter high-precision camera, enabling an efficient “whole-to-part” measurement logic through intelligent hardware collaboration. This design philosophy stems from a deep understanding of industrial production needs—during quality control, engineers must verify both the overall dimensional compliance of workpieces and the micro-precision of critical functional areas. Traditional methods often require multiple setups or equipment changes, whereas the Image3 Series seamlessly integrates both measurement modes within a single instrument.

The wide-field camera system is optimized for rapid scanning of large workpieces. Its 100mm diameter field of view enables a single image to cover a 300×200mm working area, proving invaluable for full-dimension measurement of automotive components, large machinery parts, and similar products. Optically, the wide-field mode employs a specialized large-aperture telecentric lens that effectively eliminates perspective distortion common in conventional lenses at the edges, ensuring consistent measurement accuracy across the entire field of view. Paired with a 20-megapixel high-resolution sensor, the system maintains sufficient pixel density to identify 0.02mm-level features even at wide fields, meeting most standard dimensional inspection requirements.

When measuring microstructures or tight tolerances, the instrument automatically switches to high-precision camera mode. A dedicated 25mm-diameter camera paired with a high-magnification telecentric lens boosts optical magnification to 0.375x or higher (depending on model), reducing the object-side size per pixel to less than 1μm. This precision level adequately addresses challenging tasks such as precision gear tooth profile analysis and microscopic defect detection on cutting tool edges. Notably, the high-precision mode achieves genuine resolution enhancement through comprehensive optical and hardware upgrades, rather than simple digital magnification. This avoids the image blurring and information loss inherent in digital varifocal.

The synergistic workflow between these two modes exemplifies the intelligent design of the Image3 series. During measurement, the system first uses a wide-field camera to rapidly locate the workpiece and complete most routine dimensional measurements. It then automatically identifies areas requiring high-precision verification through image analysis, guiding the measurement platform to position these sections at the center of the high-precision camera's field of view. This “survey-first, focus-later” approach not only ensures measurement accuracy but also significantly reduces unnecessary high-precision scanning of specific areas, cutting overall measurement time by over 50%. In tool measurement applications, this intelligent switching mechanism has demonstrated the ability to boost inspection efficiency from the conventional 15-20 minutes per piece to under 5 minutes per piece, while delivering more comprehensive quality data.

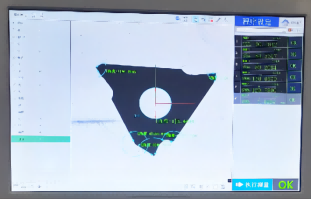

Application Example 1: Tooling Industry

In the tool manufacturing industry, traditional contact measurement methods are not only inefficient but also struggle to capture complete cutting edge profile data. Image-based dimension measuring instruments (Flash Measurement Instruments) rapidly locate tool positions using wide-field cameras, then switch to high-precision cameras to measure critical parameters such as cutting edge radius and clearance angle. This enables comprehensive “one-button” inspection, reducing measurement time to milliseconds while achieving accuracy within ±3μm.

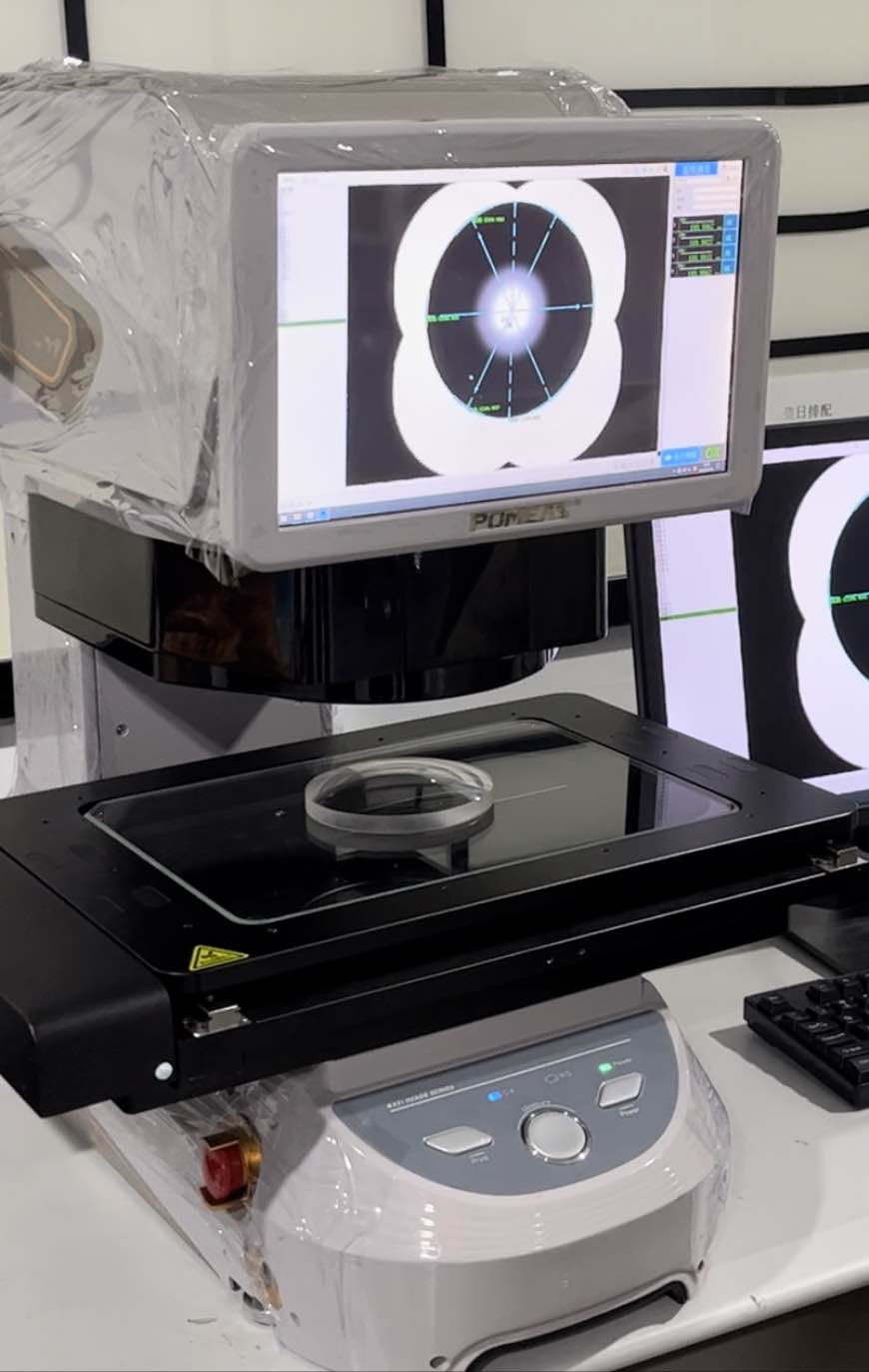

Application Example 2: Jewelry Industry

The Image Dimension Measuring Instrument (Flash Measurement Instrument) excels in this field, featuring an innovative optical compensation algorithm that automatically corrects the reflective properties of different materials. When inspecting diamond settings, a wide-field camera first determines the overall dimensions of the ring shank, followed by a high-precision camera performing micrometer-level measurements on each diamond's prongs to ensure symmetry and uniformity. For gold or platinum components with highly reflective surfaces, the system employs a polarized light attachment to eliminate mirror-like reflection interference, enabling clear imaging of microscopic scratches or welding defects on metal surfaces.

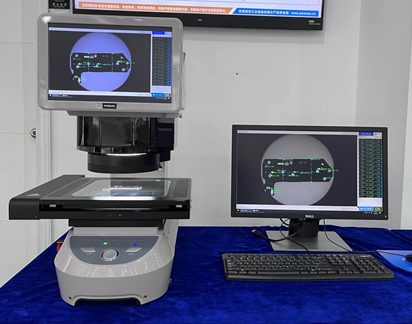

Application Example 3: Electronic Components

The dual-camera configuration of the Image Dimension Measuring Instrument (Flash Measurement Instrument) resolves the challenge faced by traditional measuring instruments in simultaneously capturing both the overall dimensions of PCB boards and the minute details of micro-components. The Wide-Field Mode enables a single scan of circuit boards up to 300×200mm, rapidly measuring overall dimensions and connector positions. Upon automatic switching to High-Precision Mode, it precisely measures positional deviations and solder joint morphology of micro-surface-mount components as small as 0402 or even 0201 packages.

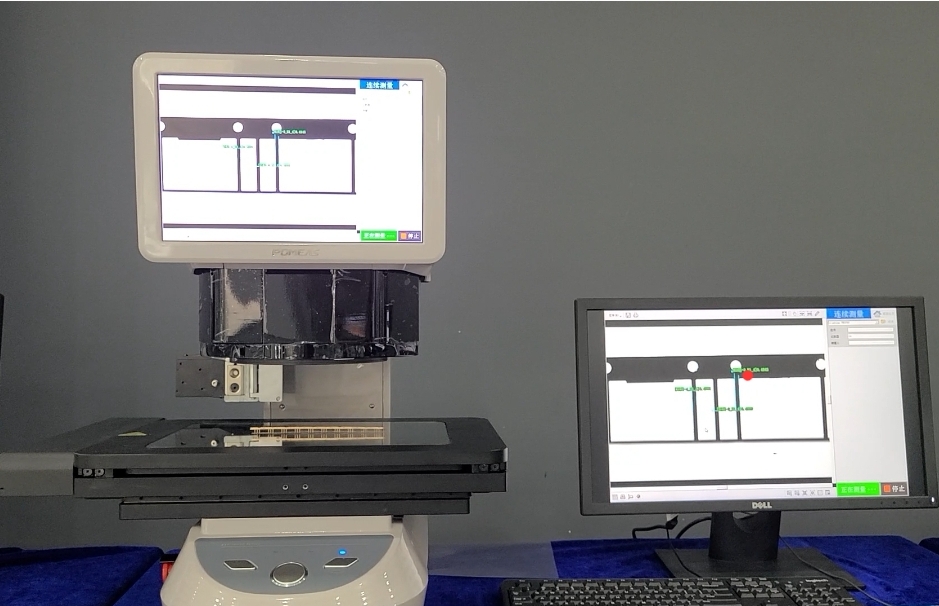

Application Example 4: Inspection of Large Mechanical Components

The wide-field mode of the image dimension measuring instrument (Flash Measurement Instrument), combined with its automatic stitching algorithm, enables rapid acquisition of complete dimensional data for large workpieces such as automotive transmission housings. The high-precision mode is employed for measuring geometric tolerances on critical components like gear bearing housings.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com