Hardware Analysis of Image Dimension Measuring Instrument - Light Source Edition

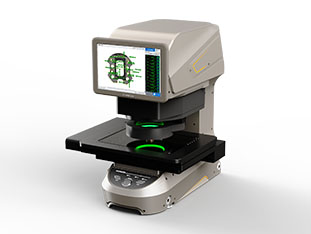

In the field of precision measurement, image dimension measuring instruments stand out for their extensive measurement range and high-efficiency measurement speed. They effortlessly handle both precise control of two-dimensional dimensions and detailed scanning of three-dimensional contours. Within their complex and sophisticated measurement systems, the light source serves as a critical component, directly impacting the accuracy and reliability of measurement results. Take the POMEAS IMAGE3 series image measuring instruments as an example. This series incorporates three built-in light sources: backlight, gap light, and surface light, and is equipped with an optional external coaxial light source.

Built-in Bottom Light: Transparent and translucent, outlining contours

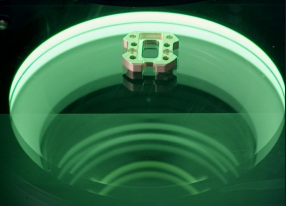

Underlight is typically mounted beneath the stage of an image dimension measuring instrument, with light shining upward from below onto the object being measured. Its primary function is to provide fundamental illumination for measurement, particularly suited for objects with transparent or translucent properties.

When light passes through such objects, specific optical effects occur within the material, enabling the object's contours, edges, and internal structures to be clearly imaged on the image sensor. For instance, when measuring transparent objects like glassware or plastic films, bottom lighting highlights variations in thickness, internal defects, and edge profiles. This assists the measurement system in accurately capturing dimensional information, ensuring precise measurement results.

Built-in Gap Light: Penetrates deep into crevices to reveal intricate details.

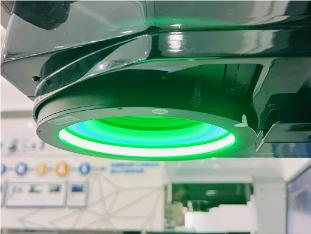

The design purpose of gap light is to measure objects featuring gaps, crevices, or groove structures. It generates light beams at specific angles and intensities that penetrate deep into the object's gaps, creating distinct light-dark contrasts along the gap edges.

By capturing images formed from these light-dark variations, the measurement system can precisely identify parameters such as gap width, depth, and shape. For instance, in scenarios like measuring the gap between a chip and substrate in electronic components or the clearance between mating parts in mechanical components, gap illumination plays a crucial role by providing reliable lighting conditions for high-precision gap dimension measurement.

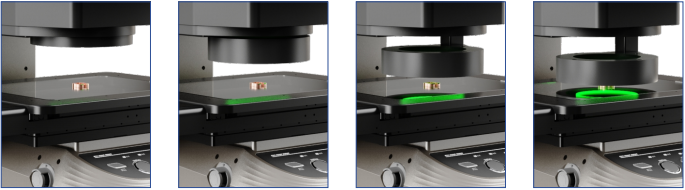

Built-in Surface Light: Even illumination that highlights features

Surface light primarily illuminates the surface of the object being measured, providing sufficient and uniform illumination for measuring the object's surface dimensions, shape, and surface characteristics. It eliminates image interference caused by reflections, shadows, and other factors on the object's surface, making surface details more clearly visible.

When measuring surface flatness, roughness, and defects (such as scratches or pits) on objects like metal parts and plastic products, surface lighting ensures the measurement system acquires high-quality images for accurate analysis of surface parameters. Additionally, surface lighting can adjust illumination angles and intensity according to specific measurement requirements, adapting to various complex surface measurement tasks.

External Coaxial Light (Optional): Eliminates glare for precise measurement

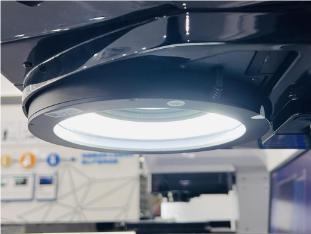

Coaxial light is a specialized light source configuration where the light beam is aligned coaxially with the optical axis of the measurement system. This design enables the light to illuminate the surface of the measured object at a perpendicular angle, and the reflected light also returns along the same axis to be captured by the image sensor.

The primary advantage of coaxial illumination lies in its ability to effectively eliminate glare and shadows caused by reflected light from object surfaces. It is particularly suitable for measuring objects with highly reflective surfaces, such as mirrors and metallic glossy surfaces. In these measurement scenarios, coaxial light delivers clear, interference-free images, enabling measurement systems to accurately identify object edges and features. This significantly enhances measurement accuracy and reliability. Due to its outstanding performance, coaxial light is often offered as an optional light source, providing users with a superior illumination solution for specialized measurement requirements.

The four light sources in the POMEAS IMAGE3 series each play a unique and irreplaceable role. Working in tandem, they provide comprehensive and precise illumination support for the measurement system, meeting diverse measurement needs across various industries and objects. Whether rigorously controlling product quality in manufacturing or conducting high-precision experimental research in scientific fields, this series of image measuring instruments, with its exceptional light source design and outstanding measurement performance, will serve as a reliable measurement partner. It empowers industries to achieve more efficient and precise measurement goals, driving continuous advancement toward higher standards.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com