Vertical Image Dimension Measuring Instrument for Measuring Thread Rolling Dies

In precision manufacturing systems, thread rolling dies serve as the “core tooling” for thread processing. Their tooth profile accuracy and pitch consistency directly determine the assembly precision and operational safety of downstream products. From miniature screws in electronic devices to heavy-duty bolts in construction machinery, even minute errors in thread rolling dies can lead to product performance failures or pose safety hazards. However, traditional measuring tools often struggle when encountering dies of varying sizes and installation scenarios, frequently hindered by spatial constraints and cumbersome operations. This makes it difficult to balance measurement accuracy with efficiency.

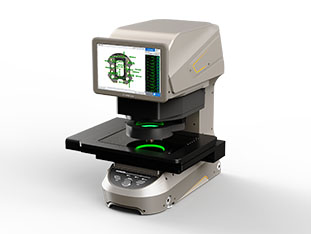

At this juncture, the vertical image dimension measuring instrument emerges as a “flexible solution” in thread rolling wheel measurement. Leveraging the unique advantages of its vertical structure, high-definition image acquisition capabilities, and intelligent analysis system, it offers a novel approach to quality control for thread rolling wheels across diverse scenarios.

Spatial Adaptation: Overcoming the Limitations of Thread Rolling Wheel Measurement Scenarios

The application scenarios for thread rolling dies are extremely diverse—ranging from standard-sized dies arranged in batches on workshop production lines, to non-standard dies awaiting R&D testing in laboratories, and even large dies installed on machining equipment that are difficult to disassemble. Traditional horizontal measuring instruments, constrained by their horizontal layout, often lack sufficient space when measuring large dies or performing in-situ inspections. The vertical structure design of the vertical image dimension measuring instrument fundamentally resolves this challenge.

The instrument employs a vertical workbench + top-mounted optical system layout. The workbench vertically supports the thread rolling wheel, while the high-resolution optical lens above precisely captures workpiece details from top to bottom. This eliminates the need for additional horizontal space, enabling effortless measurement operations even in confined workshop corners or alongside equipment. For thread rolling wheels mounted on processing equipment, select vertical models support a movable measuring arm design. This allows flexible adjustment of the measurement position, enabling “in-situ inspection.” This avoids the loss of precision and time consumption associated with disassembling the thread rolling wheel.

High-definition imaging: Precisely captures the minute features of thread rolling wheels.

The tooth profile and pitch deviation of thread rolling wheels often require micrometer-level measurement accuracy to meet production demands. The vertical image dimension measuring instrument combines “high-definition optical imaging with intelligent algorithms” to precisely capture the minute features of thread rolling wheels, enabling rapid and accurate parameter measurement.

Equipped with a 20-megapixel industrial CCD camera and a 20-megapixel dual-side telecentric lens, the instrument clearly captures contour details at the tooth crest and root of thread rolling wheels, even identifying minute wear marks on tooth surfaces. Multiple light sources effectively eliminate surface reflection interference, ensuring uniform and clear imaging to provide high-quality image foundations for subsequent measurement analysis. Professional measurement software automatically identifies over 20 critical parameters, including tooth profile angle, pitch error, and cumulative pitch deviation, with measurement accuracy reaching 0.0005mm and repeatability error ≤0.001mm—significantly surpassing manual measurement precision. Additionally, the software supports “image comparison analysis,” overlaying actual thread rolling wheel images with standard drawing profiles to visually highlight deviation locations, enabling operators to quickly pinpoint issues.

Smart and Efficient: Streamlining Thread Rolling Wheel Measurement Operations

In mass production scenarios, the measurement efficiency of thread rolling wheels directly impacts production line throughput. Traditional measurement methods require manual adjustments to workpieces and manual data recording, which are not only inefficient but also prone to human error. The vertical image dimension measuring instrument, featuring fully intelligent design throughout the process, significantly simplifies operational steps and boosts measurement efficiency by 4-6 times.

The instrument features an electrically adjustable workbench supporting automatic X and Y-axis positioning. Operators simply place the thread rolling wheel on the workbench, and the instrument rapidly identifies the measurement area via its “Auto Edge Detection” function. During measurement, the software automatically completes image capture and parameter calculation without manual intervention, eliminating human error. Upon completion, the system automatically generates standardized reports containing measurement data, deviation analysis, and image annotations. These reports support export to PDF and Word formats and can directly interface with enterprise MES systems for real-time data upload and quality traceability. Additionally, the instrument features a “program save” function. For threaded wheels of the same specification, operators need only set the measurement program once. Subsequent measurements can be initiated with a single click, significantly reducing repetitive operation time—making it particularly suitable for batch inspection scenarios.

Stable and durable: Designed for demanding industrial environments

Thread rolling wheel measurement devices are frequently deployed in workshop production environments. Factors such as temperature and humidity fluctuations, mechanical vibrations, and dust interference can all impact the stability and service life of measurement equipment. The vertical image dimension measuring instrument ensures stable operation in complex environments through rigorous structural design and protective treatments.

The instrument body features a high-strength aluminum alloy monocoque construction, combining lightweight design with high rigidity to effectively resist external vibration interference. The optical system employs a fully sealed dust-proof design, preventing dust ingress that could compromise imaging quality. The workbench surface is coated with wear-resistant ceramic to minimize long-term wear and extend the equipment's service life.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com