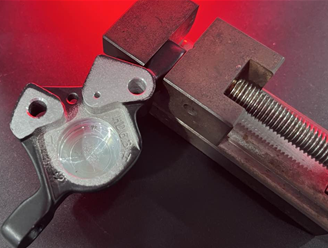

Probe scratches on blind hole inner walls causing scrap? How to implement blind hole inspection?

A、What is a Blind Hole??

A blind hole is a specialized hole structure in mechanical processing or manufacturing, characterized by being closed at one end and open at the other—meaning its depth does not penetrate the full thickness of the workpiece. Unlike through holes (which pass through both ends), the bottom of a blind hole consists of solid material, forming a closed cavity. This configuration is commonly used in scenarios requiring localized connections, fastenings, or the accommodation of specific components.

B、Blind Hole Case Study:

1. Threaded Connections: Tapping threads within blind holes enables the installation of bolts or screws for component fastening.

2. Fluid Passageways: In hydraulic or pneumatic systems, blind holes serve as one-way flow channels or fluid reservoirs.

3. Electronic Packaging: On printed circuit boards (PCBs), blind holes connect circuits across different layers without penetrating the full board thickness.

4. Mold Manufacturing: Blind holes accommodate the installation of locating pins, ejector pins, and similar components, or serve as localized structures for coolant channels.

C、Blind Hole Detection Difficulty:

1. Complex Geometric Parameters

① Depth: Precise measurement of the distance from the open end to the sealed bottom is required.

② Diameter/Taper: The diameter at the open end may differ from the bottom diameter due to manufacturing tolerances, necessitating taper inspection.

③ Surface quality: The inner wall of the sealed end may exhibit burrs, cracks, or machining marks that compromise functionality.

④ Positioning accuracy: The coordinate location of blind holes on the workpiece must meet design specifications, particularly in multi-hole arrays.

2. Limitations of Contact-Based Detection

① Probe accessibility: The probe of a traditional coordinate measuring machine (CMM) must contact both the hole wall and bottom. However, blind holes have sealed bottoms, potentially preventing the probe from fully inserting or reaching the bottom, leading to depth measurement errors.

② Risk of surface damage: Hard probes may scratch the inner walls of blind holes, affecting product performance.

③ Inefficiency: Point-by-point contact measurement is time-consuming and unsuitable for mass production.

3. Challenges of Non-Contact Detection

① Optical interference: Blind holes feature small apertures and significant depths, making it difficult for light to penetrate to the bottom, resulting in blurred imaging or reflective interference.

② Resolution limitations: Conventional optical equipment cannot clearly distinguish minute defects at the bottom of blind holes (such as cracks or burrs).

③ Data integrity: Traditional imaging systems may only capture information at the opening end, failing to comprehensively scan the internal structure of the hole.

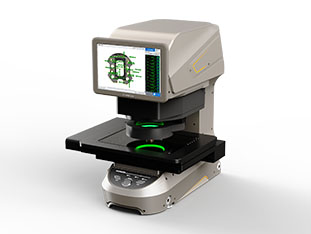

D、Inspection Solution: POMEAS High-Precision Image Measuring Instrument - Image3 max

1. Spectral Sensor Technology

① Multi-wavelength imaging: Utilizes light of different wavelengths to penetrate blind holes. By analyzing differences in reflected spectra, it enhances contrast of internal structures, enabling clear imaging even for deep holes.

② Strong anti-interference capability: Spectral filtering technology eliminates ambient light interference, improves image signal-to-noise ratio, and ensures detection stability.

2. Blind Hole Scanning Function

①3D profile reconstruction: Acquire the complete three-dimensional morphology of blind holes—including depth, diameter, taper, and other parameters—via laser scanning or structured light projection.

②Bottom defect detection: High-resolution imaging identifies minute cracks, burrs, or machining marks at the bottom of blind holes to ensure product quality.

Non-contact measurement: Eliminates probe contact to prevent secondary damage while accelerating inspection speed.

3. Application Scenarios

① Precision machining: Inspecting blind hole dimensions and positional accuracy in engine blocks, gearboxes, and other components.

② Electronics manufacturing: Measuring blind hole diameter, depth, and plating uniformity on PCBs.

③ Automotive components: Verifying seal integrity and machining quality of blind holes in cylinder heads, oil pans, and similar parts.

④ Aerospace: Assessing structural integrity of blind holes in high-temperature alloy components like turbine blades and fuel nozzles.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com