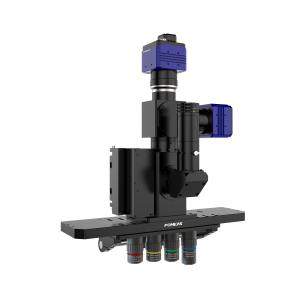

Focus X Laser Autofocus Module: Advantages Explained and Integration Examples

In the fields of precision inspection and microscopic observation, focusing accuracy and efficiency are core indicators determining equipment performance. Traditional focusing solutions are often constrained by objective lens switching speed, working distance adjustment precision, and operational complexity, making it difficult to meet the dynamic demands of high-precision, multi-scenario applications. POMEAS's Focus X laser autofocus module redefines industry standards with its breakthrough multi-objective switching technology and millisecond-level precision focusing capability (focusing time < 0.4s), positioning itself as the “intelligent focusing engine” for inspection equipment and microscopy solutions.

A、Core Advantage: Multi-objective Switching, Precise Focusing “A Step Ahead”

1. Ultra-fast focus, dynamic response < 0.4s

The Focus X module features POMEAS's proprietary high-speed laser ranging algorithm and closed-loop drive control system, achieving the entire process from trigger to precise focus in under 0.4 seconds—over three times faster than traditional solutions. Whether performing rapid positioning at low magnification or detailed observation at high magnification, the module delivers instant focus upon movement, completely eliminating efficiency bottlenecks caused by focusing delays.

2. Full-scene adaptive, with micrometer-level focusing precision

Utilizing high-precision laser displacement sensors and intelligent compensation algorithms, the module continuously monitors surface height variations in real time. It automatically corrects deviations caused by environmental vibrations or sample movement, ensuring stable focusing accuracy within ±1μm. Even in challenging scenarios such as complex curved surfaces, transparent materials, or reflective surfaces, it achieves “one-time focusing for sustained clarity throughout the process.”

3. Seamless objective switching, stable and shake-free

The module supports switching between different magnification objectives and automatically loading focus parameters within 0.1 seconds, requiring no manual intervention throughout the process. Its unique dynamic focal plane locking technology eliminates mechanical vibrations during objective changes, preventing image blurring or data deviation, and provides reliable assurance for high-precision inspection.

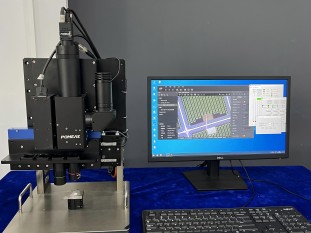

4. Compact design, plug-and-play

The module features an integrated design, reducing its volume by 40% compared to traditional solutions. It can be easily embedded into various inspection equipment or microscope systems. Paired with a dedicated mount, it enables rapid construction of a standalone multi-objective laser focusing workstation without complex modifications, significantly lowering equipment upgrade costs.

B、Application Scenarios: From precision inspection to microscopic observation, empowering the entire process.

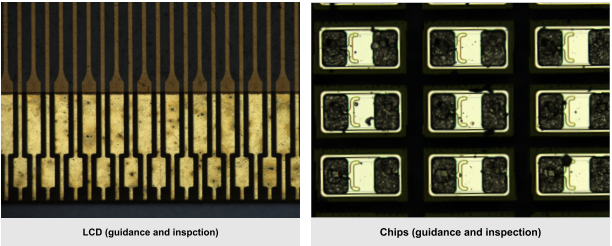

1. Inspection Equipment: Dual Enhancement in Efficiency and Precision

In applications such as semiconductor chip inspection and surface defect screening for 3C products, the Focus X can integrate with high-speed imaging systems to enable rapid scanning and precise focusing across multiple objectives. For instance, in wafer inspection, the module supports seamless switching between 5X and 100X objectives. With a focusing time of <0.4 seconds, it reduces the inspection cycle per wafer to seconds, significantly boosting production line throughput.

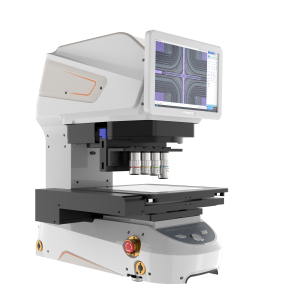

2. Microscope Solution: Integrated Observation and Measurement

When integrated with a microscope, Focus X enables simultaneous real-time focusing and dimensional measurement. Users can directly obtain three-dimensional dimensional data of samples on high-definition microscopic images without manually adjusting focus or switching measurement modes. This makes it suitable for dynamic observation and quantitative analysis in fields such as materials science and biomedicine. For instance, in live cell culture research, the module can automatically track cell movement trajectories while maintaining continuous clear imaging, providing reliable data support for scientific research.

3. Industrial Automation: Adaptable to Multiple Sample Formats

For irregular workpieces or flexible materials on production lines, Focus X's intelligent focusing algorithm automatically identifies sample contours and adjusts the optical path to ensure the target area remains locked during high-speed transport. Its focusing speed of <0.4 s perfectly matches the cycle time of automated equipment, significantly reducing scrap rates.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com