Image Measuring Instrument | Special Measurement Elements from Gears to Screws

In the precision manufacturing sector, the dimensional accuracy of components such as gears and screws directly impacts product performance and reliability. Traditional measurement methods rely on manual operation, which is not only inefficient but also susceptible to subjective factors. Equipped with its proprietary AI-Image measurement software, the POMEAS Image Dimension Measuring Instrument redefines industrial inspection standards through intelligent operation, high precision, and multi-scenario compatibility, emerging as the “efficiency engine” driving the transformation and upgrading of manufacturing.

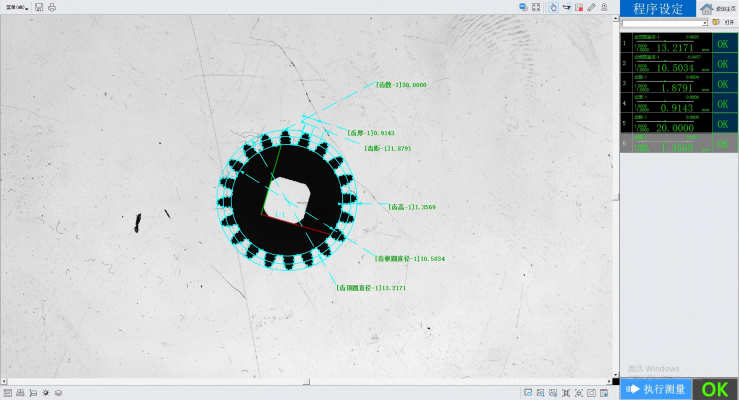

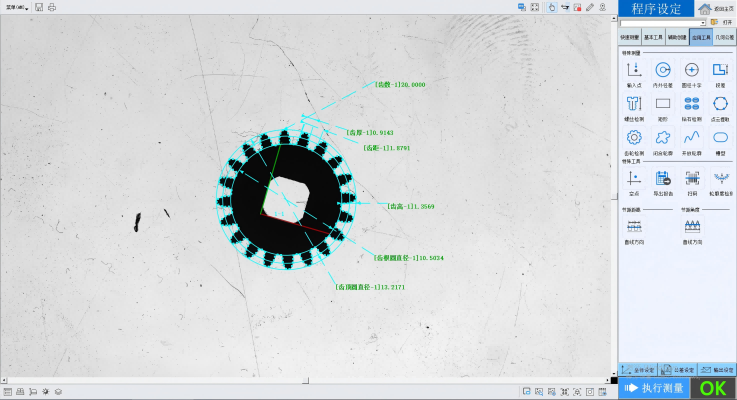

I. AI-Powered Gear Inspection: One-Click Access to Complex Parameters

As the core component of mechanical transmission, precise measurement of gear parameters such as tooth count, tooth thickness, pitch, tooth height, and root circle diameter is crucial. Pumix AI-Image software employs deep learning algorithms to achieve foolproof gear inspection:

- Smart selection, automatic recognition:Users simply need to select the gear area within the image, and the software will automatically recognize the gear profile without requiring manual adjustment of the coordinate system or selection of measurement points.

- One- click output of all parameters:Supports simultaneous calculation of over 20 key parameters including tooth count, module, pressure angle, and more. Measurement results are displayed in real time, with error controlled within ±0.005mm.

- Dynamically adapts to different tooth profiles:Whether straight, helical, or herringbone gears, the software utilizes adaptive algorithms to optimize measurement paths, ensuring precise coverage of complex tooth profiles.

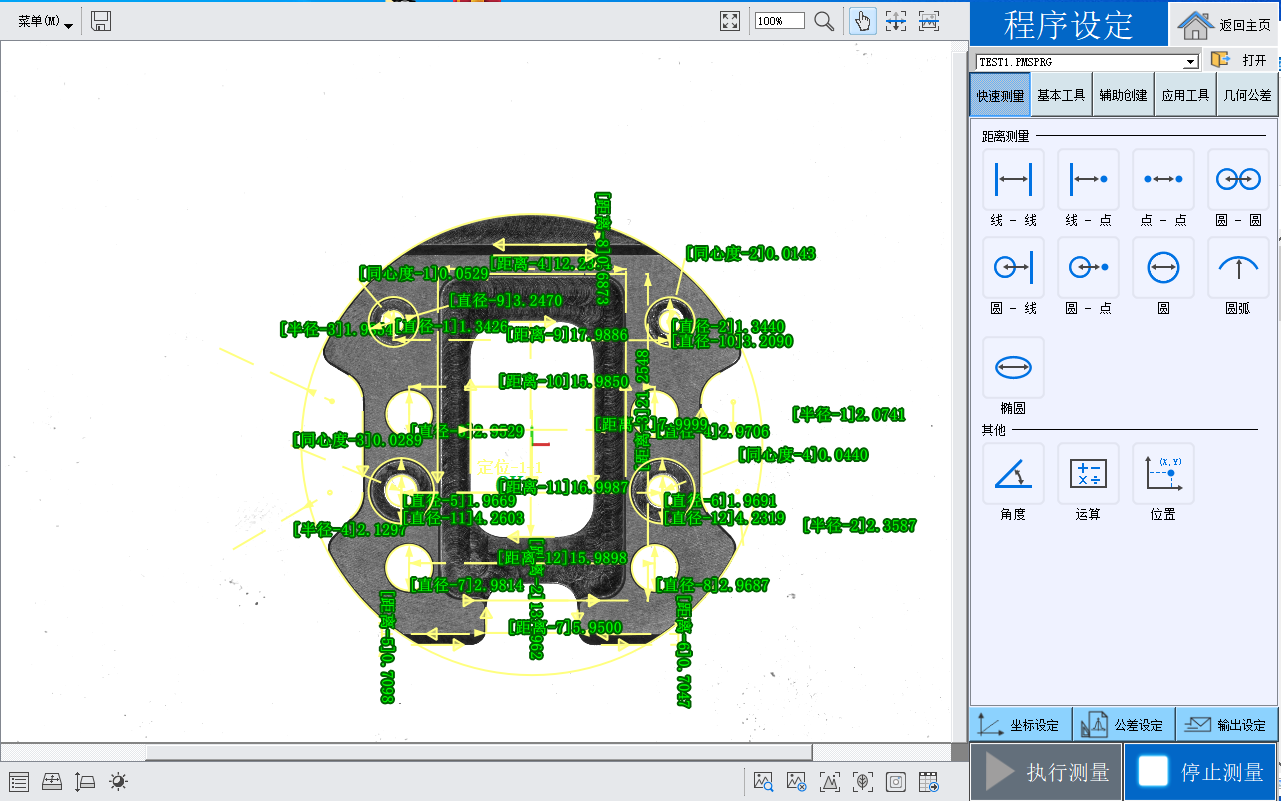

II. Full-Scene Coverage: One-Stop Inspection from Screws to Profile Accuracy

Beyond gear inspection, the AI software of the POMEAS measuring instrument integrates over 10 specialized toolkits including screw inspection, groove profile analysis, scanning modeling, and profile comparison, catering to diverse industrial applications:

1. Screw inspection: Automatically identifies thread profiles, pitch, mean diameter, and other parameters. Supports full-range M1-M50 specifications and is compatible with metric/imperial standards.

2. Groove analysis: Utilizes high-precision edge extraction algorithms to accurately measure the width, depth, and angle of V-grooves and U-grooves, with an error margin ≤0.003mm.

3. 3D Scanning modeling: Paired with a rotary workbench, rapidly generates 3D point cloud data for components, supporting reverse engineering and geometric tolerance analysis.

4. Profile comparison: Overlays measured profiles with CAD drawings for analysis, automatically marks deviation zones, and generates visual inspection reports.

III. Technological Breakthrough: AI + Optics, Redefining the New Standard for Intelligent Detection

POMEAS's core competitiveness stems from deep synergy between hardware and software innovation.:

- Super-resolution imaging technology:Equipped with high-resolution lenses and adaptive lighting, it ensures clear imaging of complex surfaces such as reflective and dark materials.

- AI Edge Computing Chip:Built-in high-performance processor enables real-time parallel processing of image processing and data analysis, with a response time of <0.1 seconds.

- Non-contact measurement:Non-contact optical measurement avoids physical damage to precision components, making it particularly suitable for demanding fields such as aerospace and semiconductors.

POMEAS Image Measuring Instruments are emerging as a key tool for enhancing competitiveness in manufacturing, leveraging three core strengths: AI algorithms, full-scenario adaptability, and unparalleled efficiency. Whether for gear manufacturers pursuing ultimate precision or flexible production lines requiring rapid response, POMEAS delivers customized solutions that empower enterprises to seize the dual high ground of quality and efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com