Can a Telecentric Measurement System measure transparent objects?

Telecentric Measurement System, as highly efficient tools in the industrial inspection field, have consistently drawn significant attention for their measurement capabilities. Particularly, the feasibility of measuring transparent objects has become a core concern for many industry users.

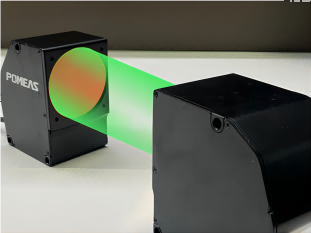

From a technical standpoint, the measurement core of such instruments lies in the synergistic operation of high-precision optical systems and intelligent algorithms. It captures object images via high-resolution industrial cameras, then employs specialized image processing software to perform grayscale analysis, edge extraction, and contour recognition. Finally, advanced algorithms calculate key parameters such as the object's dimensions and shape. The entire process employs non-contact measurement, preventing damage to the objects while enabling millisecond-level rapid inspection. This meets the high-efficiency quality control demands of production lines.

For measuring transparent objects, the key lies in whether the object can form a recognizable contour projection. Completely transparent objects are difficult to measure directly because they cannot reflect or refract sufficient light to produce clear boundaries in an image. However, in practical industrial scenarios, the vast majority of transparent products—such as glass lenses, plastic films, and acrylic components—are not absolutely transparent. Their surfaces exhibit faint reflections or refractive differences at the edges. These optical characteristics are sufficient for measuring instruments to capture contour information.

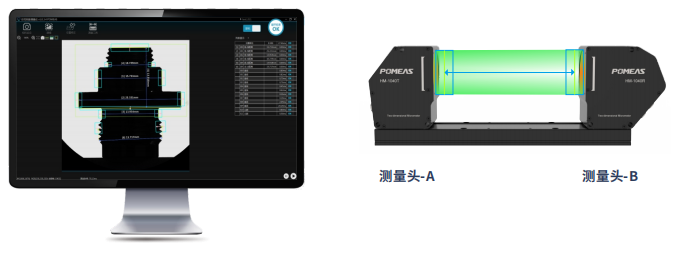

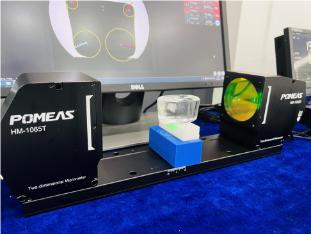

In the electronics industry, online image measurement systems can sharply capture optical contrasts between transparent objects and their backgrounds, clearly identifying even the finest edges as small as 0.1 millimeters. Paired with dedicated transparent object measurement algorithms, they effectively eliminate errors caused by light refraction, ensuring measurement accuracy down to the micrometer level.

This feature makes the Telecentric Measurement System shine in the production of transparent products. It can adapt to the inspection pace of high-speed assembly lines while providing reliable data support for product quality, making it indispensable equipment in modern industrial quality control.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION