Frequently Asked Questions About Laser Autofocus Microscopy Systems

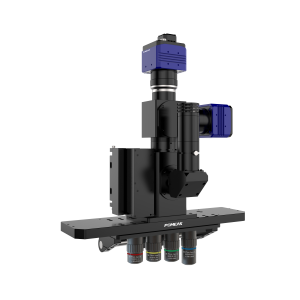

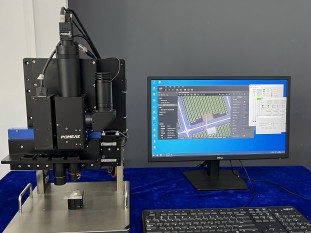

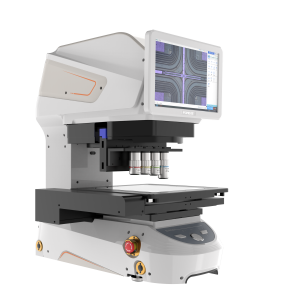

Are you frequently faced with issues such as inaccurate focusing or speeds that cannot keep up with production line rhythms in precision inspection, automated production, or scientific research observations? When dealing with reflective or unevenly thick samples, do traditional focusing methods fall short? The POMEAS Focus X Laser Automatic Focusing Microscopy System is specifically designed to tackle applications requiring high precision, high speed, and complex surfaces. Today, we will address your key questions about it and show you how it can become your reliable partner for efficiency and precision!

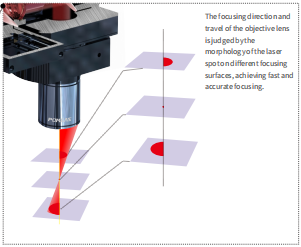

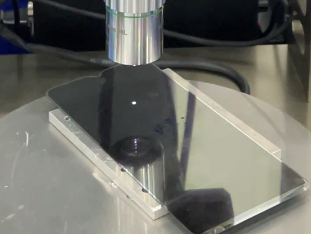

The laser autofocus microscope system uses laser triangulation and high-speed closed-loop control to achieve sub-micron accuracy and millisecond focusing. It can track uneven surfaces in real time, effectively handle reflections, and is compatible with a wide range of magnifications, making it an ideal choice for precision testing (semiconductors, PCBs, etc.) and automated production.

① Focus accuracy and time?

-

Accuracy: Up to submicron level (<1μm) or even nanometer level (<0.1μm), depending on system design, environment, and the object being measured.

-

Time: Single focus time is extremely fast, typically in the millisecond range (ms) (e.g., <10 ms or <50 ms), thanks to a high-speed processing unit, high-performance actuator, and optimized algorithms.

② What are the applications?

-

Precision inspection: Semiconductors (wafers, chips), PCBs (warping, solder joint height), precision components (dimensions, flatness), glass/displays.

-

Automated production: AOI equipment focusing, robot guidance (assembly, dispensing), online monitoring.

-

3D scanning, biological microscopy, thin film measurement, etc.

③ Can products with uneven thickness be focused in real time?

-

Yes, this is a core advantage. The system uses continuous laser scanning and high-speed closed-loop feedback to track surface height changes in real time. The Z-axis actuator responds quickly to movement, enabling seamless dynamic focusing, which is particularly suitable for complex curved surfaces, steps, or products with uneven thickness.

④ Can the reflectivity of the object being measured be accurately focused?

-

Can respond effectively. Although highly reflective surfaces pose a challenge, the system uses polarization technology (to suppress mirror reflections), intelligent algorithms (to filter out abnormal signals), and light intensity control/filter optimization to achieve precise focusing on most reflective surfaces.

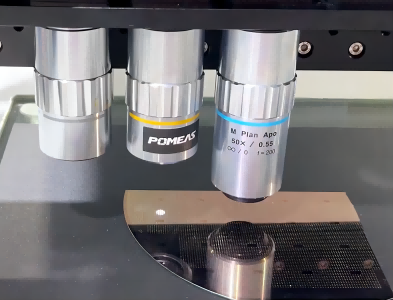

⑤ Magnification switching range?

-

Focus X is an independent Z-axis focusing module that does not determine the imaging magnification itself.

-

With excellent compatibility, it can be integrated into various microscopes or imaging systems (objectives, telecentric lenses, etc.) ranging from low magnification (such as 0.5X, 1X) to high magnification (such as 100X, 200X, or even higher), providing high-speed, high-precision autofocus support for observation at different magnifications. The magnification range depends on the integrated optical system.

After reading these answers, can the POMEAS Focus X solve your current focusing challenges at work? Whether you are pursuing extreme precision, lightning speed, or dealing with complex and variable reflections and uneven samples, it demonstrates its powerful capabilities.

Want to experience the efficiency revolution it brings for yourself? Or do you have a more specific application scenario you'd like to discuss? Feel free to contact us anytime! Our technical experts are happy to provide you with detailed solutions, demonstrations, or sample testing to help you find the optimal autofocus solution. Don't let focusing issues slow you down—take action now and unlock a new experience of efficient and accurate detection! Contact us: +86-13925702452

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com