SFS-8080K dramatically improves the efficiency of deep hole/step measurement

In today's precision measurement field, the requirements for the accuracy, speed, and versatility of measuring equipment are becoming increasingly stringent. Traditional measurement technologies are limited by their own principles and structures, and when faced with complex and changing measurement scenarios, they often find it difficult to balance high accuracy and efficiency.

Innovative Coaxial Design, Integrating Diverse Advantages

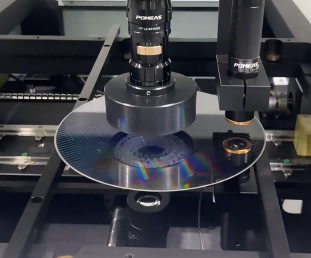

1. The SFS-8080K innovatively combines a 4K HD continuous zoom lens and a point spectrum confocal sensor coaxially, achieving perfect integration of two-dimensional vision and Z-axis point spectrum confocal. This design is not a simple superposition of functions, but a deep integration of the advantages of two advanced technologies.

2. From a visual perspective, the 4K HD zoom lens has unparalleled advantages. It has a 7.5X zoom capability and can flexibly adjust the magnification according to different measurement requirements, easily handling both macro overall observation and micro detail detection. At the same time, its 1-inch camera layout design provides a solid foundation for high-quality image acquisition. Combined with 4K high definition, it can capture extremely subtle object features and provide clear and accurate image data for subsequent precise measurements.

3. In terms of spectral measurement, spectral height measurement is a key feature of the SFS-8080K. The point spectral confocal sensor utilizes spectral confocal principles to determine surface height information by measuring the spectral distribution of reflected light. This measurement method offers extremely high precision and stability, unaffected by factors such as surface color or material, enabling precise measurement of various complex surfaces.

4. Within the limited device space, the two functions are seamlessly integrated, not only saving space but also avoiding interference and errors caused by complex device layouts. Additionally, the two-dimensional vision and Z-axis spectral measurement functions complement each other: vision can quickly locate the approximate position and range of the measurement target, guiding the spectral measurement; spectral measurement provides precise Z-axis height information, with both functions working together to significantly enhance measurement efficiency and accuracy.

Superior Performance, Breaking Through Traditional Limitations

1. The SFS-8080K demonstrates exceptional performance in terms of operational capabilities, with multiple metrics significantly outperforming traditional lenses. Its extended working distance and depth of field enable measurements at greater distances and across broader depth ranges without the need for frequent adjustments to the device's position, thereby greatly enhancing measurement convenience and efficiency. Additionally, the measurement field of view offers an 110% larger measurement range compared to traditional lenses, allowing for the coverage of a larger measurement area in a single scan, thereby reducing the number of measurements required and minimizing time costs.

2. In terms of accuracy, the SFS-8080K achieves ultra-high precision levels in coaxial spectroscopy, with accuracy below 2 microns. This precision metric leads the field in precision measurement applications, meeting the stringent measurement requirements for high-precision components. Whether it's tiny electronic components or precision mechanical parts, it can perform accurate measurements to ensure product quality meets standards.

3. Rapid focusing and scanning capabilities are another key feature of the SFS-8080K. It can focus quickly, instantly capturing clear images, significantly reducing measurement preparation time. Additionally, the spectrometer can perform rapid point cloud scanning without stopping, enabling fast and comprehensive measurement of object surfaces. In terms of scanning measurements for step differences, flatness, and contour accuracy, its speed and precision outperform traditional measurement methods. Traditional measurement methods may require multiple measurements and complex data processing, while the SFS-8080K can complete high-precision measurement tasks in a short time and generate detailed measurement reports, providing strong support for quality control in the production process.

Deep Collaboration for Efficient Measurement

1. The coaxial design of the spectrometer and zoom lens, as well as the same working distance, allow the spectrometer's point and the visual center point to coincide perfectly. This feature brings great convenience and advantages to measurement. Vision can assist the spectrometer in quickly locating the measurement target. Operators can quickly determine the position and characteristics to be measured through clear visual images, and then accurately align the spectrometer measurement point with the target without the need for cumbersome adjustment and calibration processes.

2. When measuring specified features such as deep holes, traditional measurement methods often require moving the spectral sensor to a specific position for measurement, which is complex and prone to errors. However, the SFS-8080K, with its unique design, enables rapid measurement of specified features such as deep holes without moving the spectral sensor. This not only improves measurement efficiency but also ensures measurement accuracy and stability.

3. Additionally, the device supports rapid creation of spectral measurement programs by visually selecting measurement points. Operators can use an intuitive visual interface to select measurement points on an image, and the system automatically generates the corresponding spectral measurement program. This convenient programming method significantly reduces the time required to write measurement programs, lowers operational complexity, and enables even non-professionals to quickly master the system.

Widely Used, Helping Industry Upgrade

1. The SFS-8080K, with its outstanding performance and unique design, has a wide range of applications across multiple industries. In the field of image-based visual measurement, it can achieve high-precision measurement of various parameters such as object size, shape, and position, making it widely used in industries such as electronics manufacturing, mechanical processing, and automotive parts. By conducting precise measurements of products, it can promptly identify quality issues during the production process, ensuring products meet design requirements and improving product quality and production efficiency.

2. The image rapid focusing function enables this device to play a crucial role in quality inspection and monitoring. On production lines, it can quickly and accurately inspect products, promptly identifying non-conforming items to prevent defective products from entering the market. Additionally, it monitors real-time changes in product dimensions during production, providing data support for process adjustments and optimizations.

3. The spectral height measurement and point cloud scanning and measurement functions provide powerful tools for 3D measurement and reverse engineering. In fields such as aerospace and mold manufacturing, it is necessary to perform precise measurements and modeling of complex 3D objects. The SFS-8080K can quickly and accurately obtain 3D point cloud data of object surfaces, generate precise 3D models through data processing and analysis, and provide important references for product design, manufacturing, and improvement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com