Line laser profile sensor: Meets the high-precision inspection requirements of the 3C industry

Line laser profile sensors are based on laser triangulation technology. They project a line laser onto the surface of an object, and the reflected light is projected onto a photosensitive element through an optical lens group to form a light spot. Changes in the surface height of the object cause the spot position to shift. By combining the geometric relationship between the camera and the laser source, an algorithm converts the shift into three-dimensional coordinates. With its non-contact, high-precision, and high-speed measurement characteristics, it has become a key tool for precision manufacturing and quality inspection in the 3C industry.

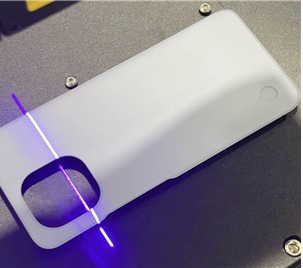

1. Smartphone Manufacturing:

① Screen flatness inspection: Precisely measure the flatness of the screen glass or assembly to ensure display performance and touch sensitivity. Accuracy requirement: error ≤ 0.01mm.

② Camera module coplanarity detection: Quickly detect the relative height of multiple camera lenses or sensor bases to ensure imaging quality and appearance consistency. Accuracy requirement: micron level.

2. Semiconductor Packaging:

① Chip Pin Coplanarity/Height Difference Measurement: High-precision measurement of chip pins (such as BGA solder balls, QFP/LGA pins) coplanarity and height difference, with a precision requirement of up to 0.5μm, ensuring the reliability of subsequent welding processes and preventing defects such as cold soldering and short circuits.

3. PCB/PCBA Inspection:

① Component positioning and height matching: Using high-precision height matching algorithms, quickly and accurately locate various components on the board (such as chips, capacitors, and connectors) to verify that their installation positions and heights comply with the design.

② Connector solder pin height anomaly detection: Efficiently identifies anomalies in the height of connector solder pins (such as USB and FPC connectors), such as warping, collapse, or cold soldering, to ensure reliable electrical connections and smooth subsequent assembly.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION