In high-end manufacturing fields such as aerospace, automobile manufacturing, and semiconductor packaging, the measurement of step height (height difference) of precision parts is a core component of quality control. Traditional contact-based measurement methods are prone to scratching the surface of workpieces, while traditional non-contact solutions are significantly affected by lighting conditions and reflectivity, making it difficult to meet micron-level precision requirements. Laser profile scanning sensors, with their non-contact, high-precision, and full-profile scanning capabilities, are emerging as a disruptive solution for precision step height measurement.

I. Technological Breakthrough: “Microscopic” Capture of Three-Dimensional Contours

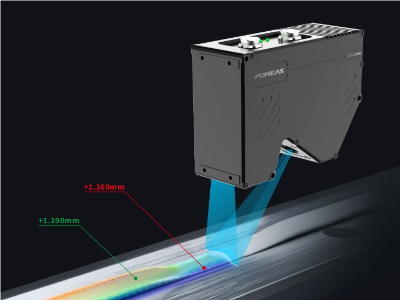

The laser contour scanning sensor uses line laser projection technology to capture the deformed contour of the laser on the surface of the part through a high-speed CMOS camera. Combined with the principle of triangulation, it can generate real-time 3D point cloud data of the measured object. Its core advantages are:

- Sub-micron accuracy: Measurement repeatability of ±0.1 μm, easily handling 0.001 mm step detection.

- Full contour coverage: tens of thousands of measurement points can be obtained with a single scan, completely restoring the surface morphology of the part and avoiding local sampling errors.

- Highly dynamic adaptability: Supports high-speed mobile measurement (up to 5 m/s) and can be embedded in production lines to achieve 100% online detection.

- Resistance to environmental interference: Optimized laser wavelength design effectively filters stray light in the workshop and maintains stable measurement on highly reflective and dark surfaces.

II. Application of The Solution: Full Coverage from Laboratory to Production Line

1. Embedded production line measurement: real-time defect interception

In automotive engine block machining production lines, laser contour scanning sensors can be integrated into the end of robotic arms or above conveyor belts to dynamically scan the step differences on the sealing surfaces of engine blocks. The system is linked with a PLC, and when a step difference exceeds the tolerance (e.g., >0.05 mm), it immediately triggers an alarm and automatically sorts out defective products, intercepting quality incidents at the source of production. According to actual test data from a certain automotive parts manufacturer, this solution has reduced the production line's missed inspection rate to 0.02%, saving over 2 million yuan in rework costs annually.

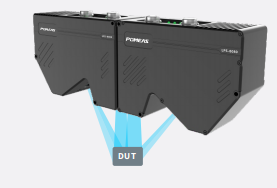

2. Offline inspection station: “CT scan” for complex parts

For complex-shaped parts such as turbine blades and precision gears, a multi-sensor array scanning system can be set up. Through multi-angle laser projection and point cloud stitching algorithms, full-size 3D modeling can be achieved, enabling precise measurement of key parameters such as blade tip step differences and tooth profile errors. An application by a certain aviation company shows that this solution improves detection efficiency by 5 times compared to a coordinate measuring machine, and does not require manual marking points, reducing the operating threshold by 70%.

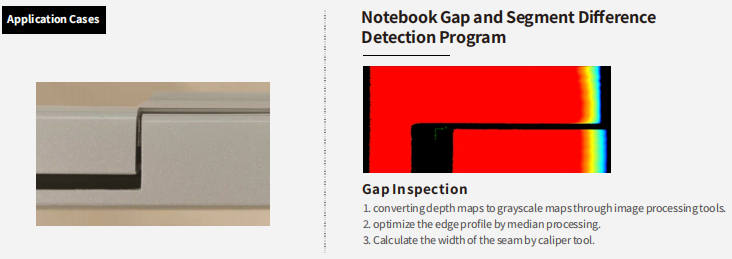

3. Reverse engineering during the R&D phase: accelerating product iteration

In the development of new consumer electronics products, laser contour scanning sensors can quickly obtain step data of competitor product shells, assisting designers in optimizing structural tolerances. Combined with dedicated software, they can also generate STL format digital models that can be directly used for 3D printing verification, shortening the R&D cycle by 40%.

III. Value of the Plan: Dual Guarantee of Cost Reduction, Efficiency Improvement, and Quality Enhancement

- Cost optimization: Non-contact measurement reduces probe wear, with a single sensor life exceeding 100,000 hours; online detection avoids batch scrapping, reducing overall costs by more than 60%.

- Efficiency leap: From traditional sampling inspection to full inspection, measurement speed is increased by 10-20 times, supporting 24-hour continuous operation.

- Quality traceability: Original point cloud data can be archived for a long time, enabling full-chain quality traceability of the production process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com