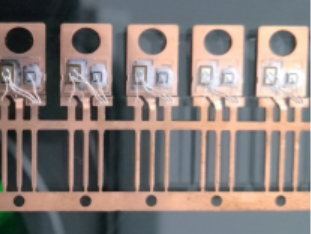

Stamped shrapnel measurement difficulties:

Stamped shrapnel as a precision stamped parts, its measurement needs have typical “small, precise, more” characteristics:

-

Tiny size and complex shape requirements: the length and width of the shrapnel may be only a few millimeters, but the shape tolerance (such as flatness, parallelism, hole position) needs to be controlled at the micron level, the traditional calipers and micrometers are prone to deformation due to the contact force, leading to errors.

-

Interference with material and surface properties: Metal shrapnel surfaces may have reflections (e.g., plating), burrs, or oil stains that affect the imaging quality of the optical device, requiring special light sources or algorithms to compensate.

-

Batch inspection efficiency bottleneck: the production line may produce dozens of pieces of shrapnel per minute, manual piece-by-piece inspection or traditional imaging instruments need to focus and adjust the parameters frequently, it is difficult to match the production beat.

-

Multi-parameter simultaneous detection needs: in addition to length and width, but also need to measure the hole diameter, hole distance, arc height, R angle and other multi-dimensional parameters, the traditional equipment needs to be clamped several times or switch the program, time-consuming and easy to miss the inspection.

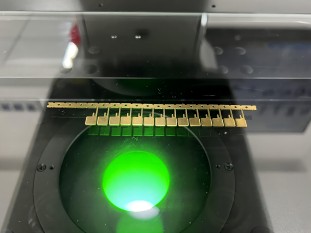

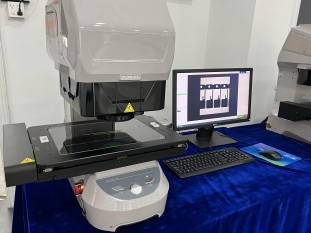

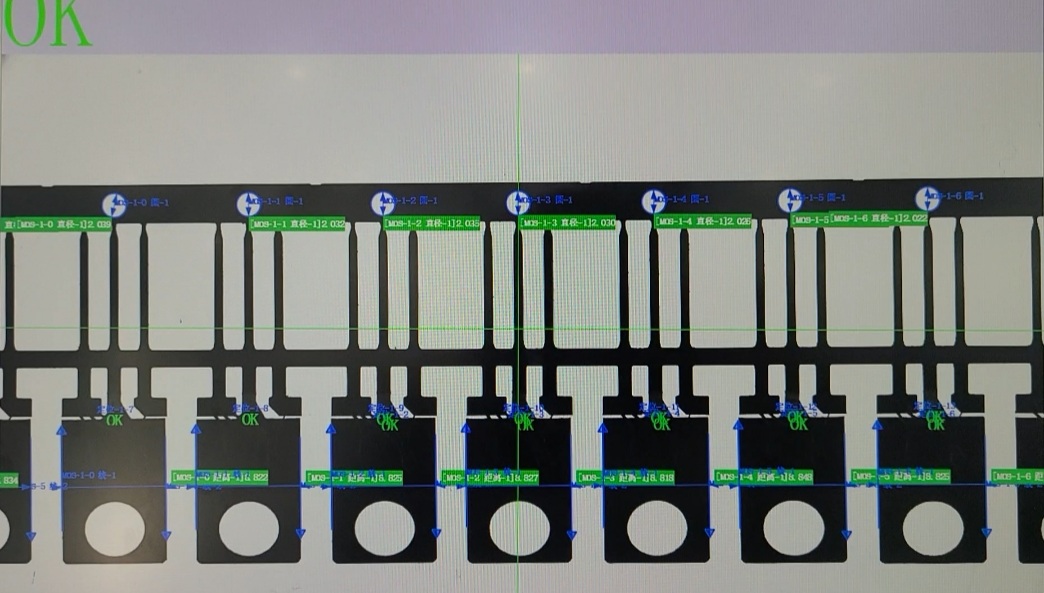

Image Size Gauge Image 3 Series

The Image 3 series of dimensional measuring instruments accurately and efficiently inspects the length, width, tolerance and other positional dimensions of stamped shrapnel at the touch of a button.

-

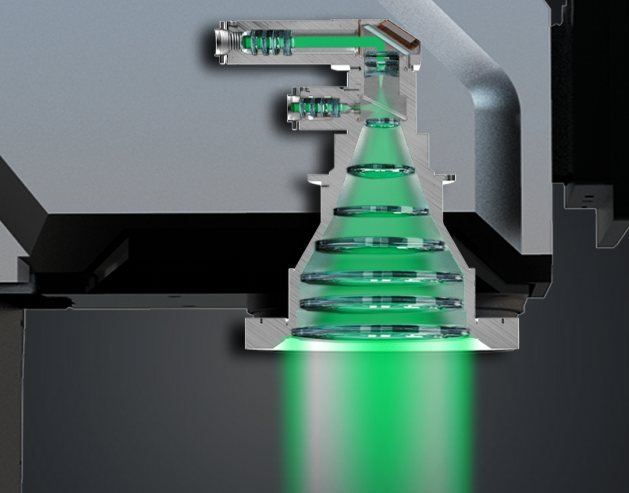

Non-contact high-speed imaging: using high-resolution industrial cameras (such as 5 million pixels level) and telecentric lenses, eliminating the risk of contact deformation, and at the same time, through the autofocus and area scanning technology, a single piece of shrapnel full-image acquisition can be completed within 0.5 seconds.

-

Intelligent Light Source Adaptation: Equipped with adjustable ring light source and polarization filter components, it automatically switches the diffuse illumination mode for reflective surfaces, suppresses the interference of high light, and ensures clear extraction of edges.

-

One-key multi-parameter inspection: Built-in special inspection template for shrapnel, supporting 20+ parameters such as length, width, hole diameter, hole distance, arc height, form and position tolerance (e.g. flatness, perpendicularity), etc. for simultaneous measurement, with no need to manually intervene in program switching.

-

Sub-pixel accuracy guarantee: Through the sub-pixel edge detection algorithm and calibration compensation technology, the measurement accuracy can reach ±1μm, which meets the demand of micron-level shape and position tolerance control.

Program Advantages

-

Qualitative Change in Efficiency:The inspection time of a single piece is shortened from more than 30 seconds in the traditional method to less than 2 seconds, and the efficiency of batch inspection is improved by more than 15 times, which is perfectly adapted to the beat of automated production lines.

-

Precision Stability:Non-contact measurement eliminates human operation error, long-term repeatable measurement accuracy is stable, avoiding leakage and misjudgment caused by manual fatigue.

-

Versatility & Flexibility:Support the rapid switching of different specifications of the shrapnel inspection program (automatically call the template by sweeping the code), to adapt to the multi-species small batch production mode.

-

Data Value Extension:Measurement results automatically generate SPC analysis reports (e.g., CpK values, trend graphs) and interface with the MES system to achieve closed-loop quality traceability and process optimization.

Image 3 series image size measuring instrument with “one-button” operation as the core, through the non-contact imaging, intelligent light source, multi-parameter simultaneous detection and other technologies, to completely solve the stamping shrapnel “measurement is not accurate, measurement is not fast, measurement is incomplete” pain points.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com