In the rapid development of intelligent manufacturing today, the industrial camera is different from the daily use of ordinary cameras, but with high precision, high speed, high stability and other characteristics, in industrial production, quality inspection, machine vision and other fields play an irreplaceable role. Next, let's walk into the world of industrial cameras and unveil its mysterious veil.

Definition and Core Functions of Industrial Cameras

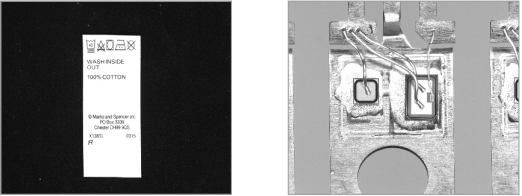

An industrial camera, also known as a machine vision camera, is a device that converts optical images into digital signals, designed for various applications in the industrial field. It can replace the human eye for measurement and judgment. Through image acquisition of the target object, combined with image processing algorithms and computer vision technology, it can realize the functions of size measurement, defect detection, and positioning recognition of the object. For example, in the production line of cell phone screens, industrial cameras can quickly detect whether there are scratches, bad dots and other defects on the screen, and the accuracy can reach the micron level, which far exceeds the detection ability of the human eye.

How Industrial Cameras Work

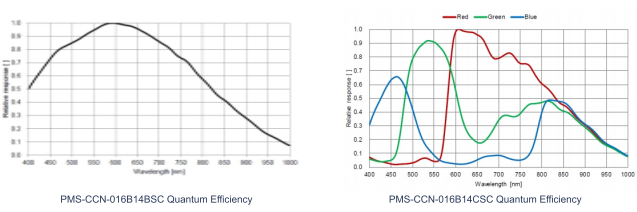

The working principle of industrial cameras is based on photoelectric conversion and digital signal processing. Light shines through the lens onto the image sensor, which is the core component of an industrial camera and is mainly divided into two types: charge-coupled devices (CCDs) and complementary metal-oxide semiconductors (CMOS). When the light irradiates the pixel unit of the sensor, it will excite the electron - cavity pairs, thus generating an electrical signal.CCD sensors output the electrical signals sequentially by means of charge transfer, which is characterized by high sensitivity and low noise, and is suitable for application scenarios with extremely high requirements on image quality, such as astronomical observation, microscopic imaging, etc.; CMOS sensors, on the other hand, have independent amplifiers for each pixel, and can directly convert the electrical signals into digital signal outputs, which has power consumption and is suitable for the application scenarios with extremely high requirements on image quality. CMOS sensors, on the other hand, have an independent amplifier for each pixel, which can directly convert the electrical signal into a digital signal output, with the advantages of low power consumption, fast reading speed, and relatively low cost, and are widely used in the fields of industrial detection, security monitoring, and so on.

After the output of electrical signals, through the camera's internal analog - digital converter (ADC) will be converted to digital signals, these digital signals and then through the camera's image processing chip for noise reduction, enhancement, correction, and other processing, and finally through the interface (eg, GigE, USB3.0, Camera Link, etc.) transmitted to a computer or other devices, by the special software for further analysis and processing, so as to achieve a variety of industrial applications. processing, thus realizing the functions of various industrial applications.

Classification of Industrial Cameras

Industrial cameras are categorized in various ways. According to the type of image sensor, it can be divided into CCD cameras and CMOS cameras; according to the color of the captured image, it can be divided into color cameras and black and white cameras. Color cameras can capture the object's color information, applicable to the need to identify color differences in the scene, such as fruit sorting, textile color detection, etc.; black and white cameras are more sensitive to light, in the detection of the object's edges, contours, and grayscale differences in the performance of the commonly used in the detection of defects in the metal surface, the quality of the printed materials inspection.

In addition, according to the camera's output signal mode, can also be divided into analog cameras and digital cameras. Analog camera output is an analog signal, through the image acquisition card will need to be converted to digital signals to be processed by the computer, has the advantage of low cost, but there is a short signal transmission distance, susceptible to interference and so on; digital camera directly output digital signals, to achieve high-speed, long-distance transmission, and anti-interference ability, is the mainstream choice in the industrial field.

Application Scenarios for Industrial Cameras

Industrial cameras have a wide range of applications, covering almost all aspects of industrial production. In the automobile manufacturing industry, industrial cameras can be used for automobile parts size measurement, assembly quality inspection and body appearance defect detection, to ensure that every car off the line meets the strict quality standards; in the field of electronics manufacturing, industrial cameras can realize the precision mounting of chips, circuit board welding quality inspection, to ensure that the performance and reliability of electronic products; in the logistics industry, industrial cameras can be used to carry out package In the logistics industry, industrial cameras can measure the volume of parcels, barcode recognition, improve the efficiency and accuracy of logistics sorting; in the food industry, industrial cameras are used for the appearance of food inspection, weight sorting, to protect food safety and product quality.

In the food industry, industrial cameras are used for food appearance inspection and weight sorting to ensure food safety and product quality. In addition, industrial cameras also play an important role in scientific research and medical fields. In scientific research experiments, industrial cameras can be used to record the process of change in the microscopic world; in the medical field, industrial cameras can assist surgical robots to carry out precise operations, providing strong support for the development of medical technology.

Differences between industrial cameras and ordinary cameras

Although both industrial cameras and ordinary cameras can realize the function of image shooting, there are obvious differences between the two in several aspects. In terms of performance indicators, industrial cameras have higher resolution, frame rate and dynamic range. The resolution of industrial cameras can easily reach millions of pixels or even higher, the frame rate can reach dozens of frames per second, hundreds of frames, or even thousands of frames per second, able to capture fast-moving objects; whereas the frame rate of ordinary cameras is generally around 30 frames per second, which is difficult to meet the needs of the industrial field of high-speed moving objects detection.

In terms of adaptability of the working environment, industrial cameras can work stably in high temperature, low temperature, humidity, dust and other harsh environments, its protection level usually reaches IP65 and above, can effectively prevent the intrusion of dust and water; ordinary cameras are more suitable for daily use in the normal indoor or outdoor environment, the requirements of the environment is more demanding. In addition, industrial cameras have rich interfaces, which are easy to integrate with various devices, while the interfaces of ordinary cameras are mainly to meet the daily image transmission and storage needs.

As a key equipment in the field of industrial automation, industrial camera, with its unique performance and wide range of applications, promotes the development of industrial production in the direction of intelligence and efficiency. For novices, understanding the basic concepts, working principles, classification, application scenarios, and the difference between industrial cameras and ordinary cameras is the first step to enter the field of industrial vision.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com