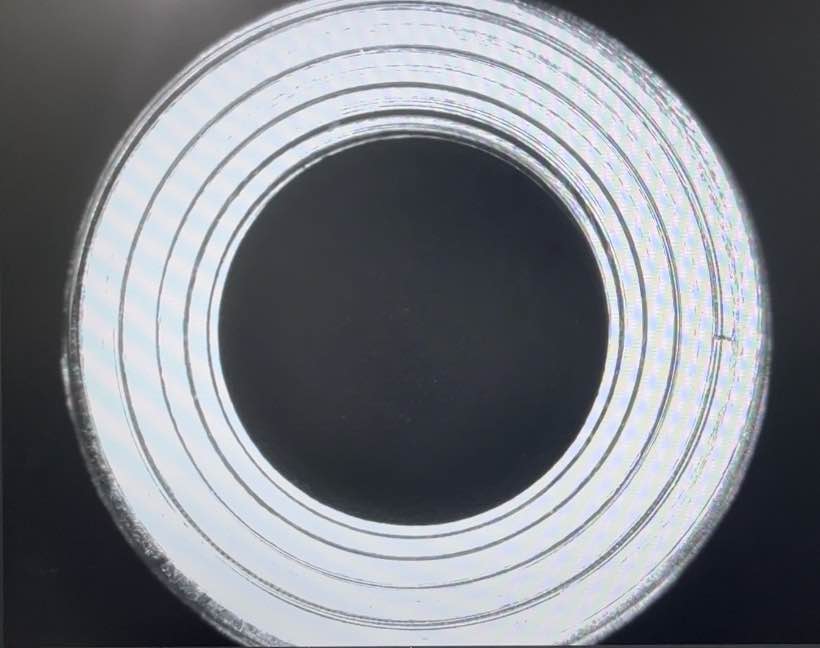

In the field of precision manufacturing in pursuit of superior quality, concentricity is one of the core geometric tolerances for measuring the quality of rotating body parts (e.g., shafts, bearings, gears, sleeves). It is directly related to the rotational balance, service life and overall performance of the product. So, what is concentricity? And how to measure it accurately and efficiently?

I. What is Concentricity?

Concentricity is based on the geometric tolerance standard, Deviation of the measured element (e.g. axis of a cylindrical or conical surface) from the spatial position of the datum axis (usually also a cylindrical axis). In short, it measures whether the centerlines of two or more cylinders (or holes) are “perfectly aligned” on the same line.

Concentricity deviation will cause rotating parts (such as motor shafts, bearings) to produce violent vibration and noise, and accelerate the uneven wear of parts, shorten the service life, and even affect the assembly accuracy and the overall performance of the product (e.g., sealing, transmission efficiency).

II. How to accurately measure concentricity?

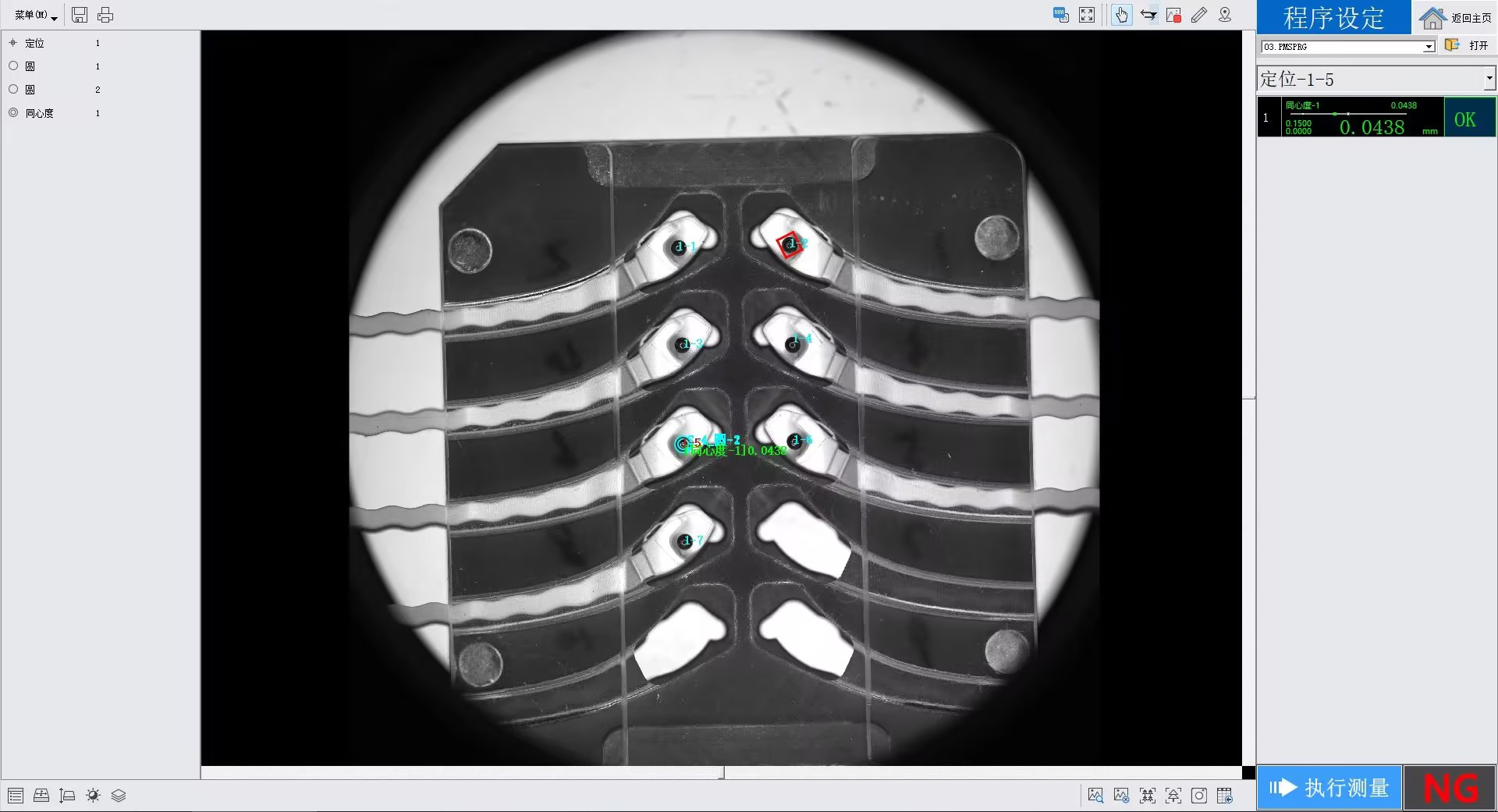

POMEAS Image Dimension Measuring Instruments provides an efficient and accurate non-contact solution for fast measurement of concentricity and 2D/3D dimensions to improve production efficiency.

III. Watch strap inspection cases:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION