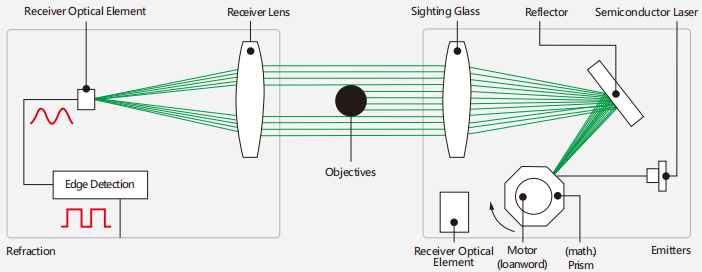

Diagram of the Principles of Laser On-Line Diameter Measuring Instrument:

Based on the laser triangulation or laser scanning method, the laser on-line calibrator calculates the diameter of an object by emitting a laser beam and receiving the light signal reflected or blocked by the object to be measured.

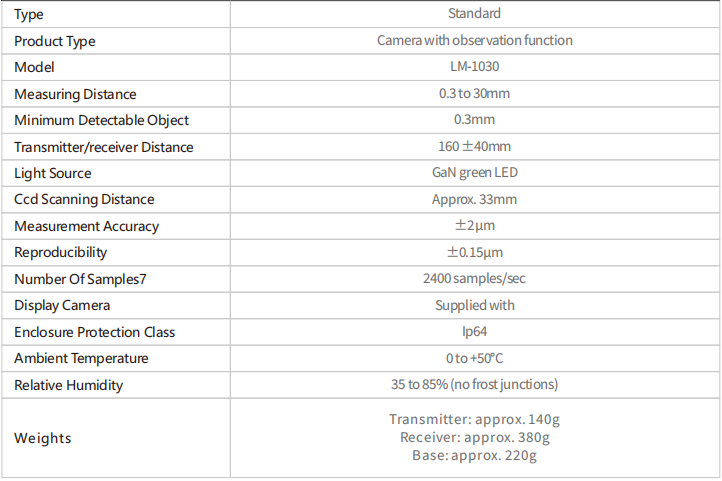

Key Technical Parameters of Laser On-Line Diameter Measuring Instruments:

(POMEAS LM-1030 parameters as an example)

Laser On-Line Caliper Applications:

1. Metal processing: online size monitoring of steel pipes, copper wires, aluminum profiles, etc.

2. Cable/Fiber: real-time detection of conductor outer diameter, insulation thickness.

3. Plastic/Rubber: Diameter fluctuation monitoring of extruded pipes and films.

4. Quality control: replace manual micrometer, realize 100% full inspection.

Recommended: POMEAS LM-1030 Laser In-Line Diameter Gauge

Ultra-compact design: small size, suitable for installation in narrow space, no need for complex mechanical structure.

1μm high accuracy: meets the needs of precision manufacturing (e.g. semiconductor, medical device parts inspection).

Real-time measurement: Sampling frequency up to 2000Hz, dynamically capturing diameter changes.

Convenient operation: one-button calibration, support touch screen or host computer software to set parameters.

Easy to install: non-contact measurement, only need to align the device with the measured area to automatically output data.

It can be applied to the diameter inspection of tiny parts (e.g. bearing balls, needles); real-time monitoring of high-speed production lines (e.g. cable, fiber optic pulling); and precision analysis of sample dimensions in scientific research experiments.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION